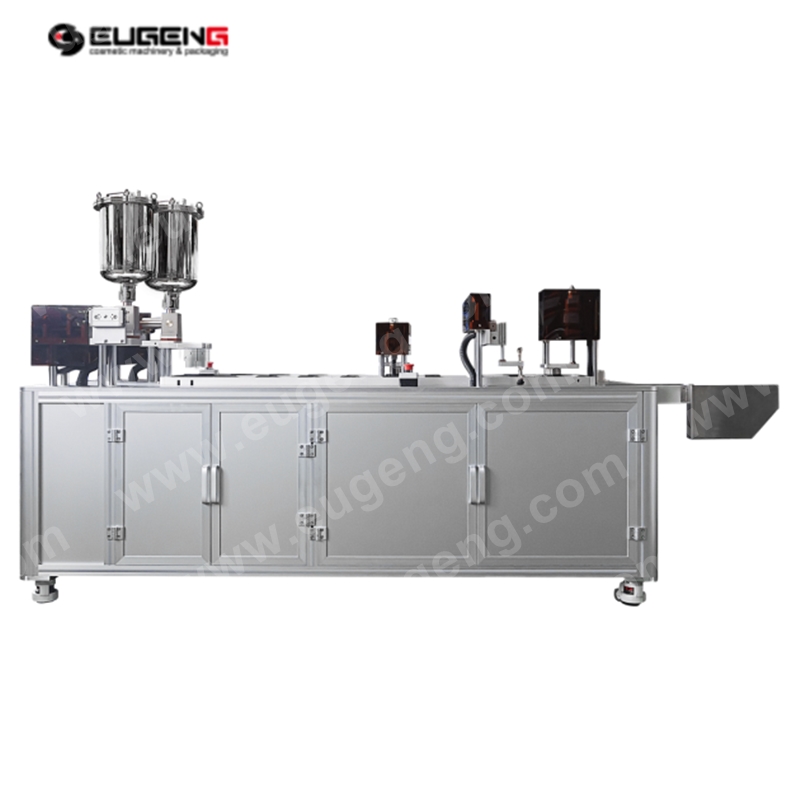

2021 Good Quality Hot Soap Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng

2021 Good Quality Hot Soap Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng Detail:

Model EGMF-02 with heating and mixing mascara filling machine is a semi-automatic filling and capping machine design for the production of high viscous cosmetic liquid,such as lip gloss,mascara eyeliner,gel,cream,suitable for filling both liquid and high viscosity paste.Heating and mixing can turn on/off based on needs.

Lip gloss

Mascara

Eyeliner

· 1 set 30L pressure tank with inner plug for high viscosity materials

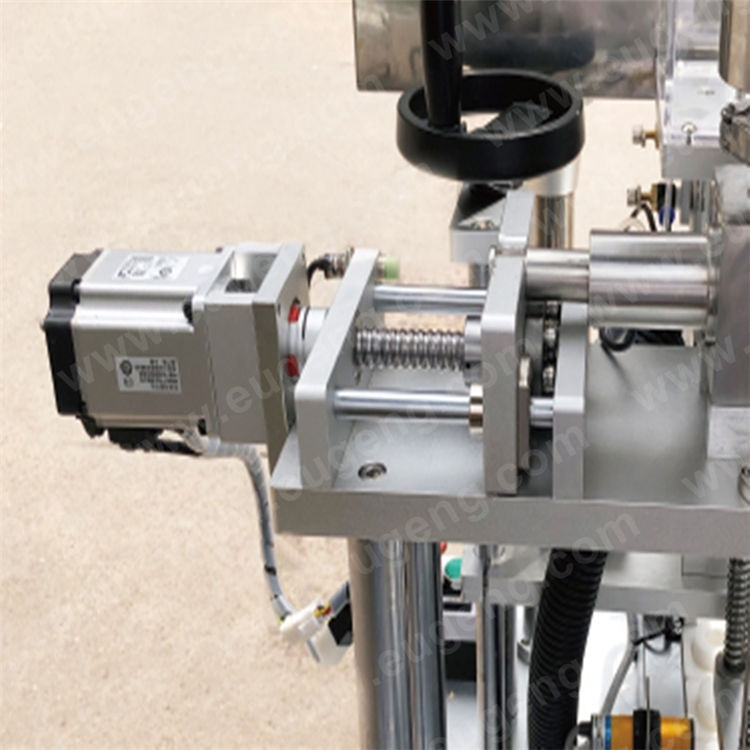

· Piston controlled dosing pump, and with servo motor driving , filling while tube moving down

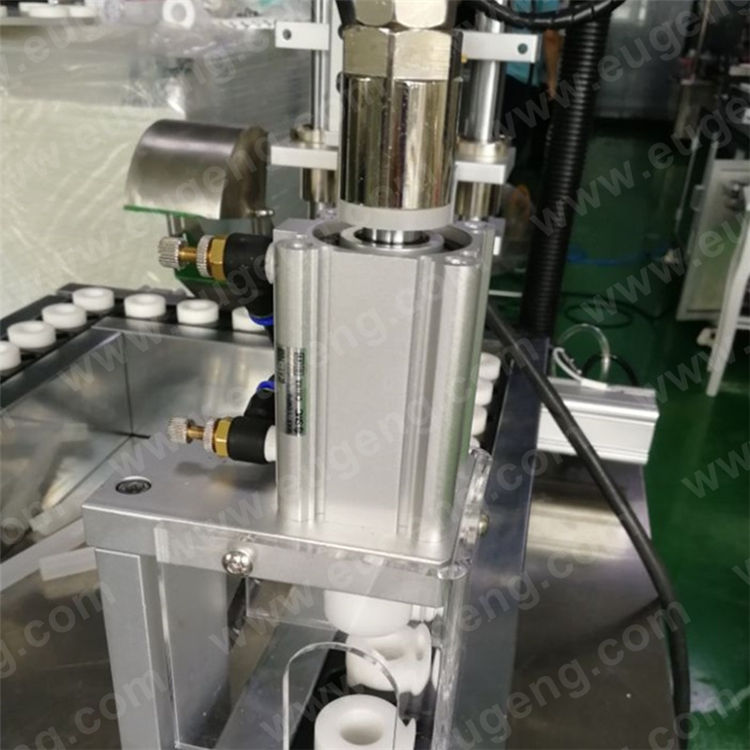

. Machine with sucking back function so that prevent dripping

· Accuracy +/-0.5%

· Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick change over

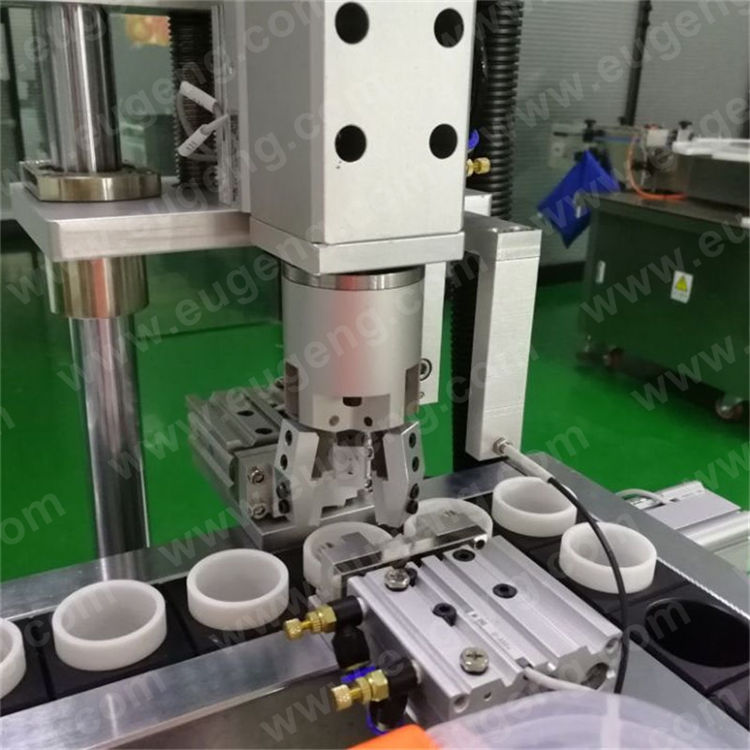

· Servo-motor capping unit with adjusted torque,capping speed and capping height also adjustable

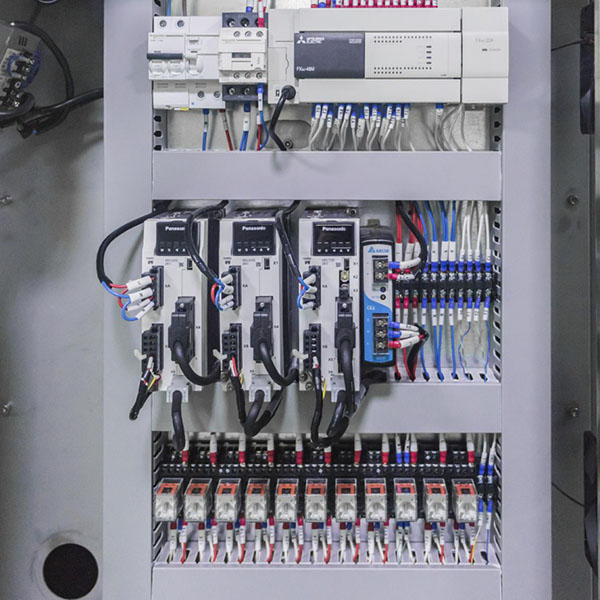

Touch screen control system with Mitsubishi brand PLC

Servo motor Brand:Panasonic Original: Janpan

Servo motor control the capping , and torques can be adjusted , and reject rate is less than 1%

Heating mixing mascara filling machine wide application :

Widely used for filling high viscosity cosmetic liquid, cream, gel, lip gloss,mascara,eyeliner etc..

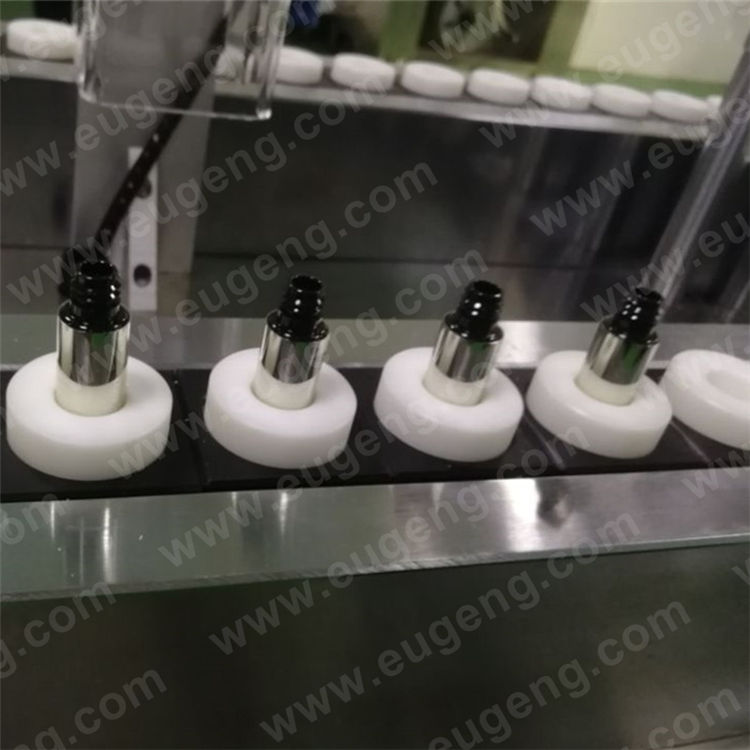

Heating mixing mascara filling machine puck customized

POM(according to the diameter of bottle)

Heating mixing mascara filling machine Capacity

30-35pcs/min

| Model | EGMF-02 with heater and mixer |

| Production type | Push Pucks |

| Output capacity/hr | 1800-2100pcs/h |

| Control type | Servo motor&Air Cylinder |

| No.of Nozzle | 1 |

| Number of pucks | 49 |

| Vessel volume | 30L/set |

| Display | PLC |

| No.of operator | 2-3 |

| Power consumption | 7.5kw |

| Dimension | 1.5*0.8*1.9m |

| Weight | 450kg |

| Air input | 4-6kgf |

Push table

Sensor for checking tubes no tube no filling

Filling nozzle with guider prevent nozzle broken

Two Pressure tanks with plug for high viscosity bulk with heated and mixer

Filling system fast cleaning and reassembly

Filling with servo motor driven, volume adjustable

Pressing wiper with cylinder,can turn on/off

Servo motor capping , torques can be adjustable

Capping head height can be easily adjusted

Different size tube just need change pucks

PLC MITSUBISHI

Servo Motor Panasonic

Pneumatic is SMC

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for 2021 Good Quality Hot Soap Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng , The product will supply to all over the world, such as: Kenya, South Korea, Czech republic, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.