Welcome to our websites!

Automatic Nail Polish Filling Machine

.Indexing turn table with 24 holes holder

.1set of 60L filling tank with heating for nail gel,without heating for nail polish

.Automatic feeding bottles table,fill balls ,loading brush vibrator,and cap loading vibrator,servo capping and auto discharge,finished product collection table

.1 set filling balls unit with automatic by cylinder,and fill 0/ 1 /2 balls once .

.Use ceramic valve

.If material with more big glitter ,Suggest use piston filling system

.Cap tightening station tightens caps to correct torque by servo motor (you can set the torque on touch screen)

.Automatic discharging with exit arm

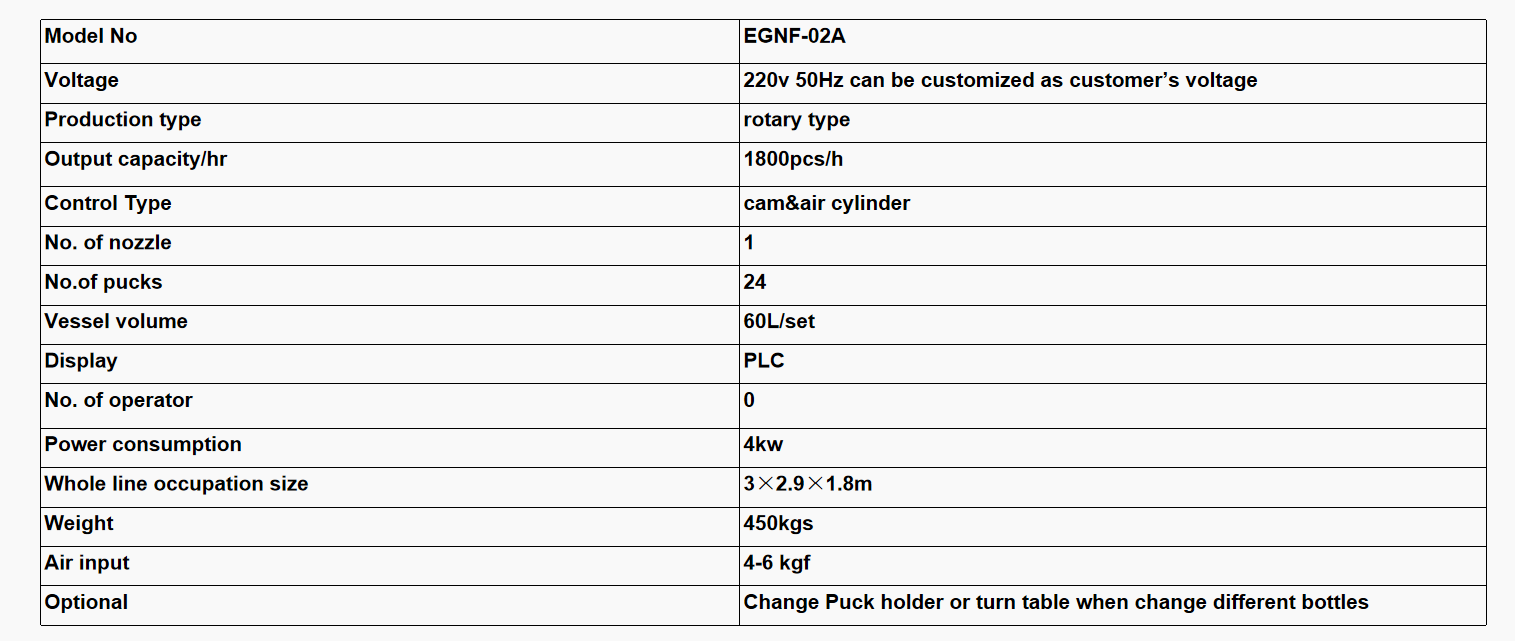

Automatic nail polish filling machine Capacity

30 bottles/min

Mold

Change puck holders or change rotary table when change different bottles

Full automatic filling capping machine

Anti-explosion

60L heating pressure tank

Feeding table to load bottle into puck

Automatic filling steel ball 1/2 once

Filling with Ceramic valve

Automatic loading brush vibrator

Automatic brush direction correction

Automatic loading cap vibrator

Automatic servo capping

Automatic discharge finished product

Finished product collection table

Write your message here and send it to us