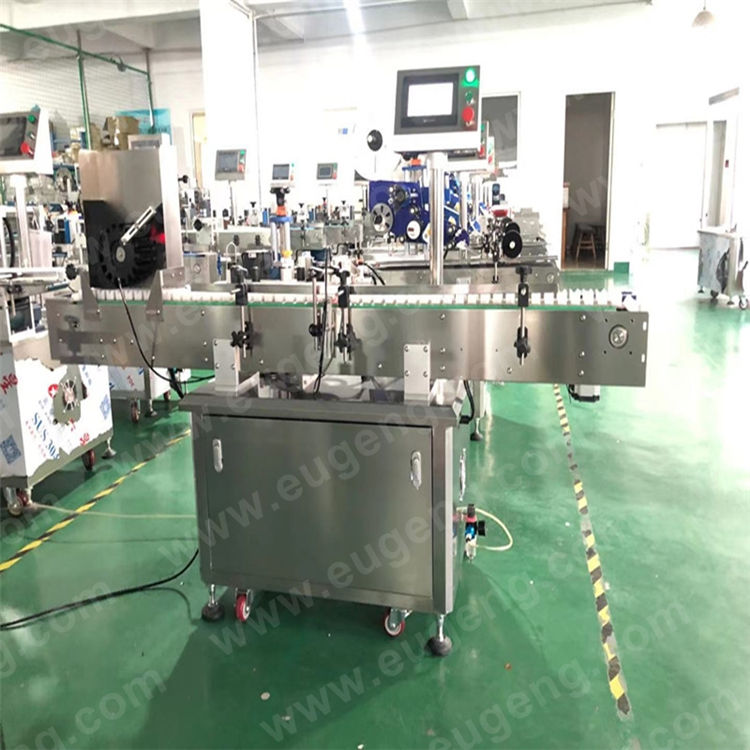

China Factory for Lip Gloss Bottom Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng

China Factory for Lip Gloss Bottom Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng Detail:

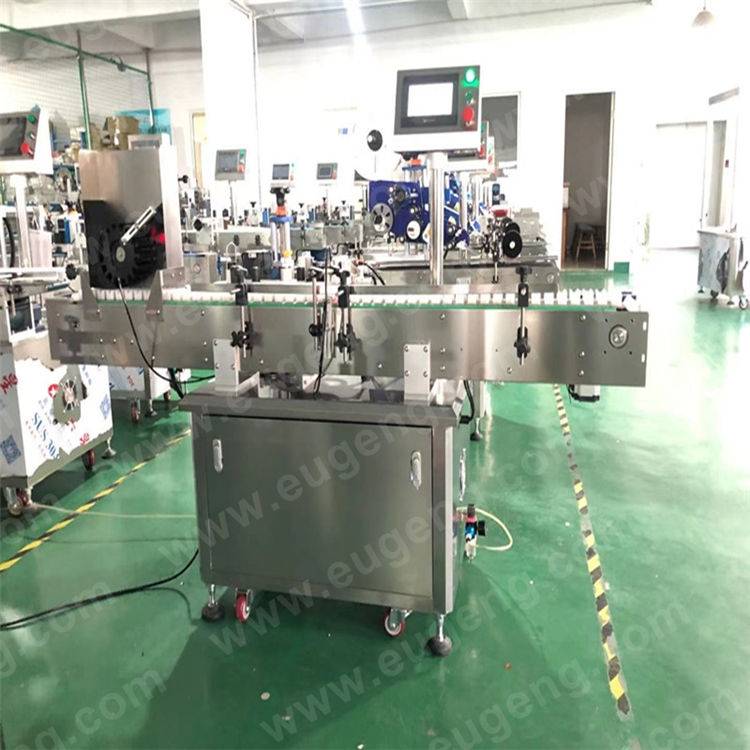

Model EGBL-600 horizontal bottom labeling machine is a semi-automatic horizontal labeling machine design for the production of slim round bottles,tube products,such as lip balm bottles,lip gloss bottles,lipstick bottles,mascara,eyeliner pen and so on.

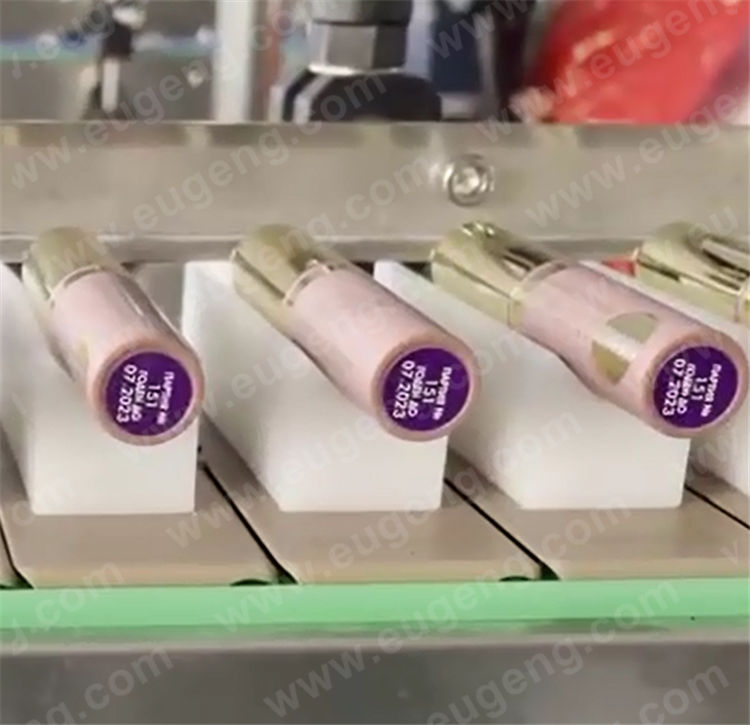

Mascara bottom labeling

Mascara bottom labeling

Lip gloss bottom labeling

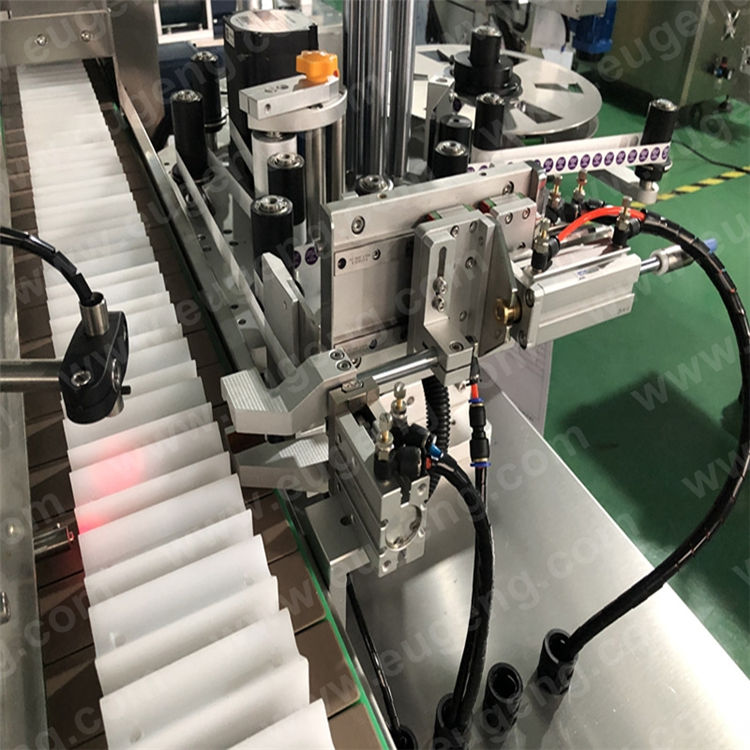

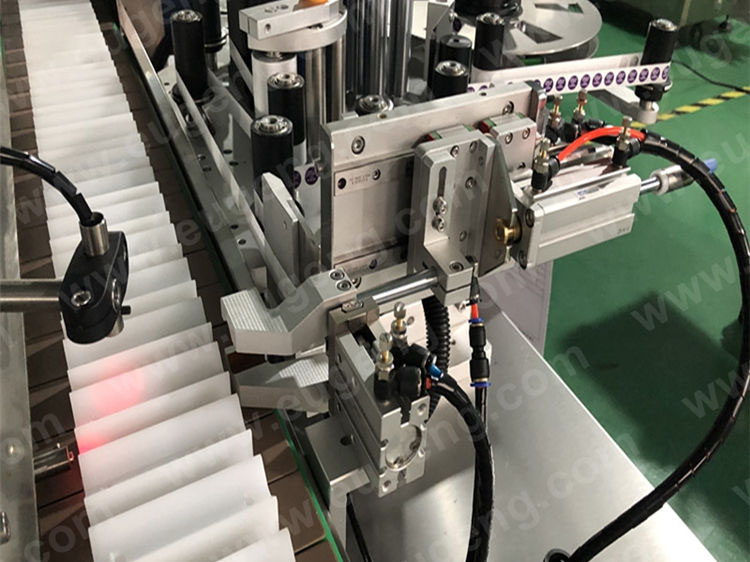

Automatic sensor check , no products, no labeling

Labeling Accuracy +/-1mm

Automatic roll label for prevent missing label

Labeling head X&Y position can be adjusted

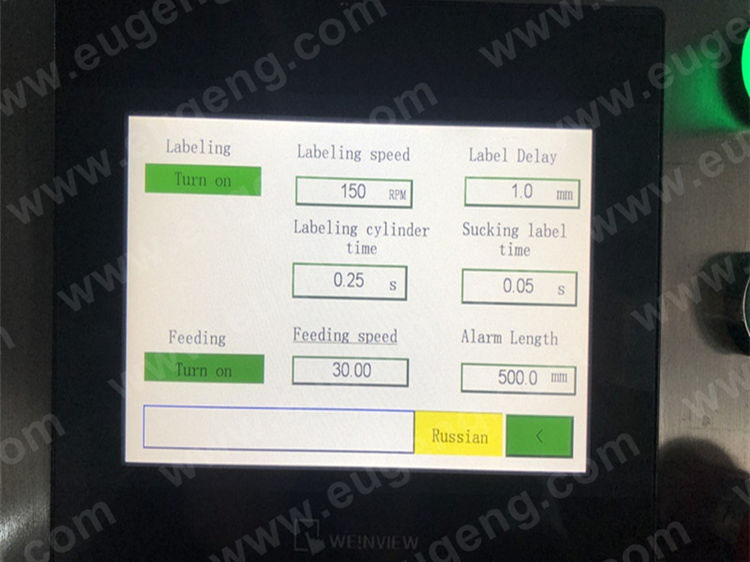

Touch screen operation

Equipped with counting function

Labeling speed,conveying speed and products feeding speed can be set on the touch screen

Label delay length and alarm length can be set on the touch screen

Labeling cylinder time and sucking label time can be set on the touch screen

Language can be customized as user’s language

Product positioning device ensures high labeling accuracy and also higher labeling speed

Horizontal bottom labeling machine Capacity

50-60pcs/min

Horizontal bottom labeling machine Optional

Transparent label sensor

Hot stamping label sensor

| Model | EGBL-600 |

| Production type | Liner type |

| Capacity | 50-60pcs/min |

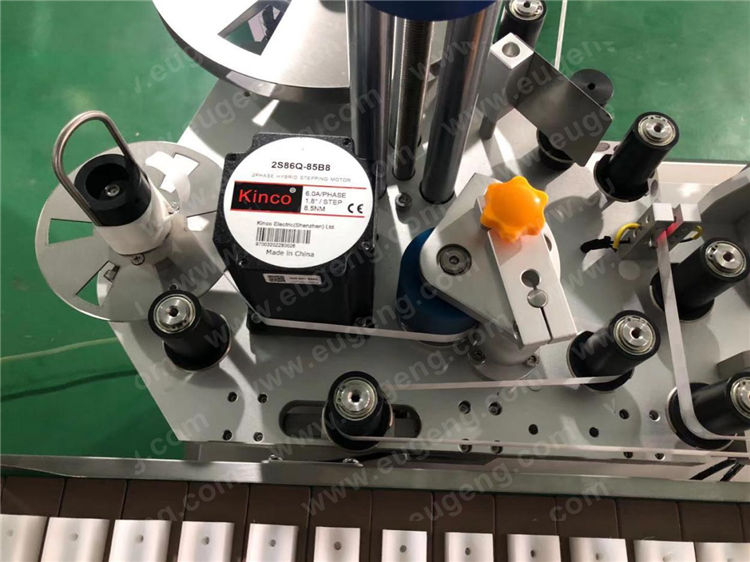

| Control type | stepper motor |

| Labeling accuracy | +/-1mm |

| Label size range | 10«width«120mm,length»20mm |

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 1kw |

| Dimension | 2100*850*1240mm |

| Weight | 350kgs |

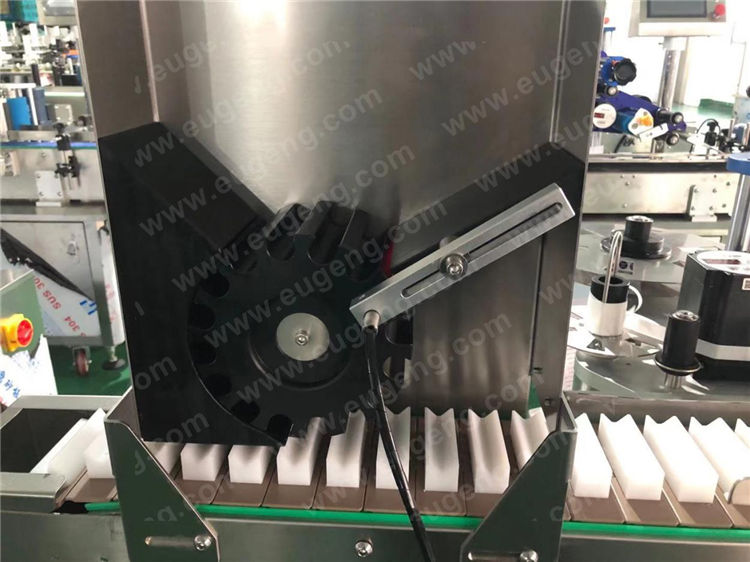

Bottles feeding hopper

Automatic check the label and correct the position

Product sensor

Labeling position can be adjusted

Stepper motor control labeling

Winding roller

PLC MITSUBISHI

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China Factory for Lip Gloss Bottom Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng , The product will supply to all over the world, such as: Swedish, Thailand, Surabaya, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.