Factory wholesale Cosmetic Pressed Powder Machine - Automatic Eyeshadow Press Machine – Eugeng

Factory wholesale Cosmetic Pressed Powder Machine - Automatic Eyeshadow Press Machine – Eugeng Detail:

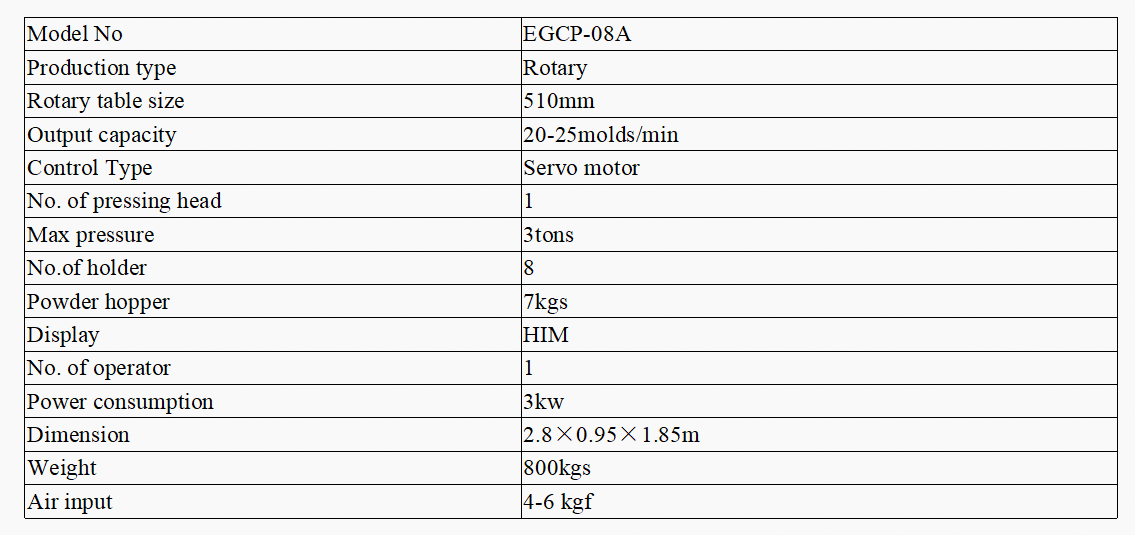

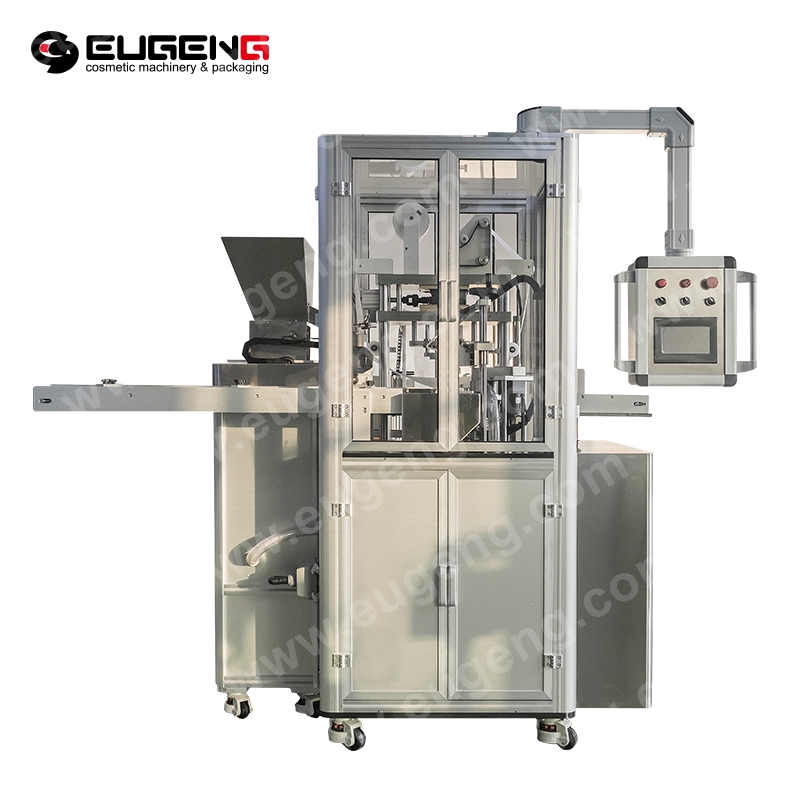

EGCP-08A automatic eyeshadow press machine is a full automatic powder press machine,designed for production of pressed face powder,two-way cake,eyeshadow,blush,highlight,eyebrow pressed powder.

Servo motor control pressing ensures high speed and stable pressing pressure.Current pressure display in the touch screen.Pressure can be set as needs in the touch screen.

EGCP-08A Automatic eyeshadow press machine is a fully automatic rotary type press machine,specially used for production of eyeshadow,pressed face powder,blush etc..

.Speed 15-20molds/minute(900-4800pcs/hour)

.Mold customized as aluminum pan size,

.For 20mm size,one mold made with 4 cavites,speed is 60-80pcs/minute,which means 3600-4800pcs/hour

.For 58mm size,one mold made with one cavite,speed is 15-20pcs/minute,which means 900-1200pcs/hour

.Tell us your aluminum pan size,let us help calculate how many cavites for one mold,then know its speed

Automatic eyeshadow press machine Features

.Operator put aluminum pan into conveyor and conveyor loading pans automatically

.Auto picking up pan and put into pan

.Auto powder feeding,with level sensor check powder positon to ensure enough powder for feeding

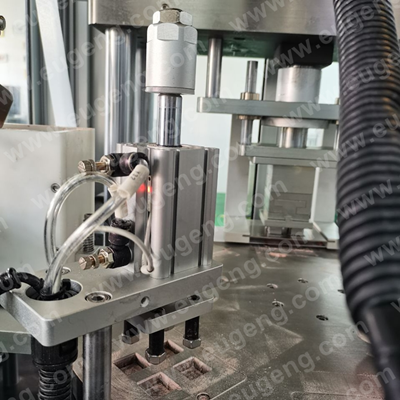

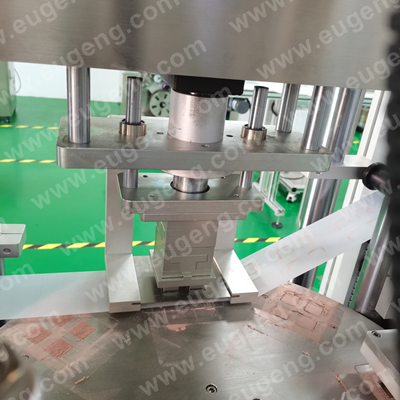

.Auto powder pressing driven by servo motor,pressing from downside and max pressure 3 tons. Pressure can be set in the touch screen

.Auto fabric ribbon winding

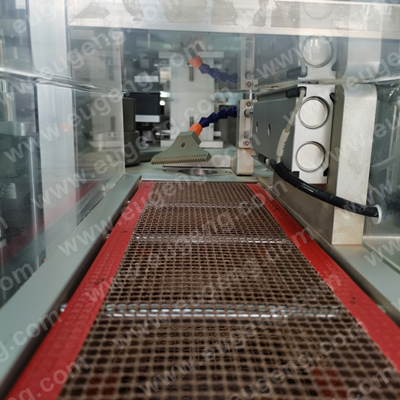

.Auto discharge the finished products,conveyor with pan bottom cleaning device. Also there is blower gun to clean the dust powder in the surface of pan

.Auto dust collection system for molds

Automatic eyeshadow press machine Components parts brand:

.Servo motor Panasonic, PLC&Touch screen Mitsubishi, Switch Schneider,Relay Omron,Pneumatic componets SMC,Vibrator:CUH

Automatic eyeshadow press machine for making compact powder,eyeshadow,blush etc..

Rotary type,total 8 sets of molds

Rotary type,total 8 sets of molds

Aluminum pan conveyor guider size adjustable as pan size

Aluminum pan conveyor guider size adjustable as pan size

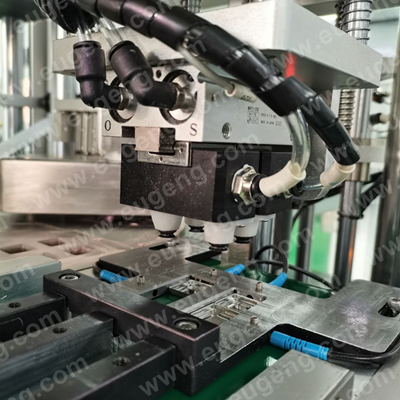

Auto picking up 4 cavities once and put into mold

Auto picking up 4 cavities once and put into mold

Auto pressing 4 pans to ensure being into mold

Auto pressing 4 pans to ensure being into mold

Auto powder feeding with level sensor check

Auto powder feeding with level sensor check

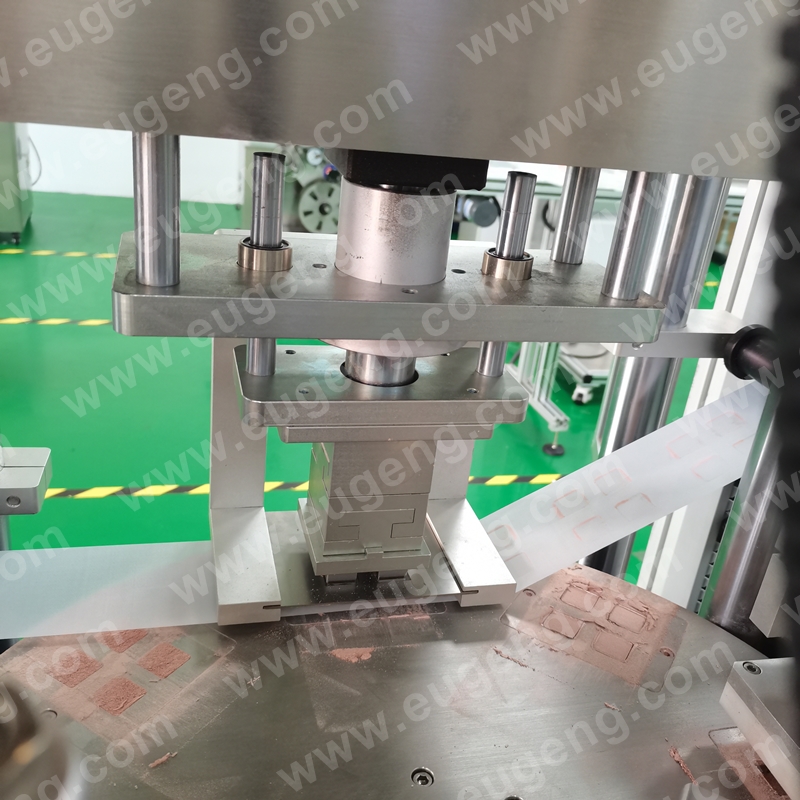

Servo motor pressing,pressure set in touch screen

Servo motor pressing,pressure set in touch screen

Auto discharge finished products then cleaning mold system

Auto discharge finished products then cleaning mold system

Pan bottom cleaning device

Pan bottom cleaning device

Discharge conveyor with blower gun to clean pan surface

Discharge conveyor with blower gun to clean pan surface

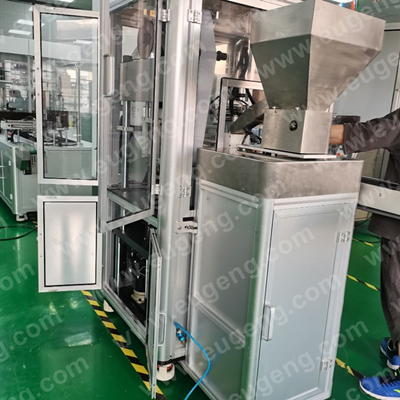

Powder hopper separated with pressing machine

Powder hopper separated with pressing machine

Powder dust collection tank under powder hopper

Powder dust collection tank under powder hopper

7kgs powder hopper in line with GMP standard

7kgs powder hopper in line with GMP standard

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Factory wholesale Cosmetic Pressed Powder Machine - Automatic Eyeshadow Press Machine – Eugeng , The product will supply to all over the world, such as: UK, Lebanon, Kazakhstan, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.