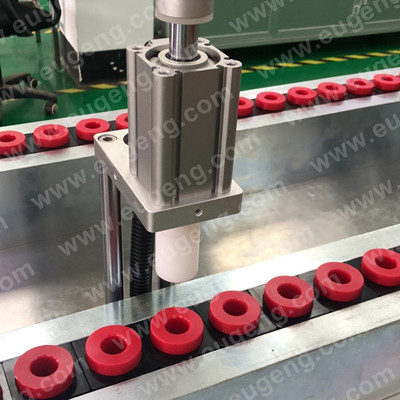

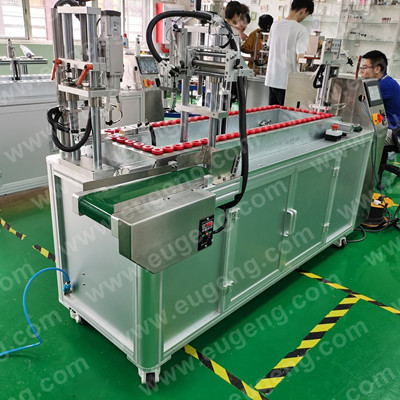

Free sample for Silicone Lipstick Mold Filling Production Line - Mascara Lipgloss Filling Machine – Eugeng

Free sample for Silicone Lipstick Mold Filling Production Line - Mascara Lipgloss Filling Machine – Eugeng Detail:

Model EGMF-02 mascara lipgloss filling machine is a semi automatic filling and capping machine,

designed for production of lip gloss,mascara,eyeliner,liquid foundation,Mousse foundation,lip concealer,gel,essential oil etc..

.1 set of 30L pressure tank with thickened pressing plate for high viscous liquid

.1 set of 60L pressure tank with filling pipe to fill liquid directly from tank(optional)

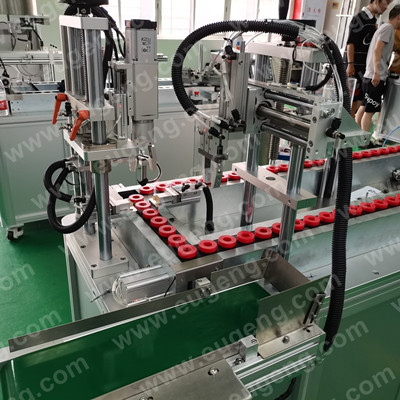

.Piston filling system,easy for color change and cleanning

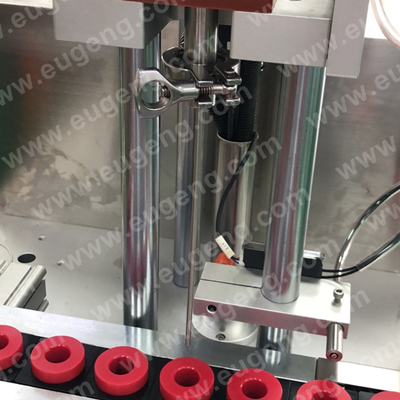

.Auto filling driven by servo motor,while filling while bottle moving down,dosing volume and filling speed adjustable

.High filling accuracy+-0.05g

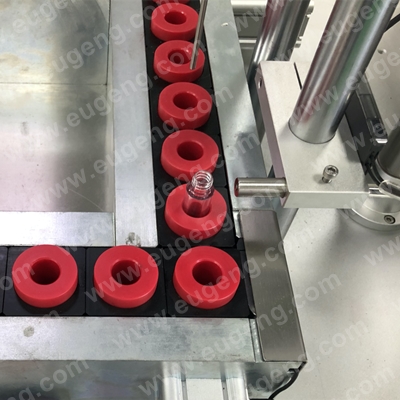

.Put plug by hand and auto plug pressing by air cylinder

.Caps sensor,no cap no capping

.Servo motor control capping,capping torque adjustable

.Auto picking up finished product into output conveyor

Mascara lipgloss filling machine Components brand

.Mitsubishi PLC,touch screen,Panasonic servo motor,Omron Relay,Schneider switch,SMC pneumatic components

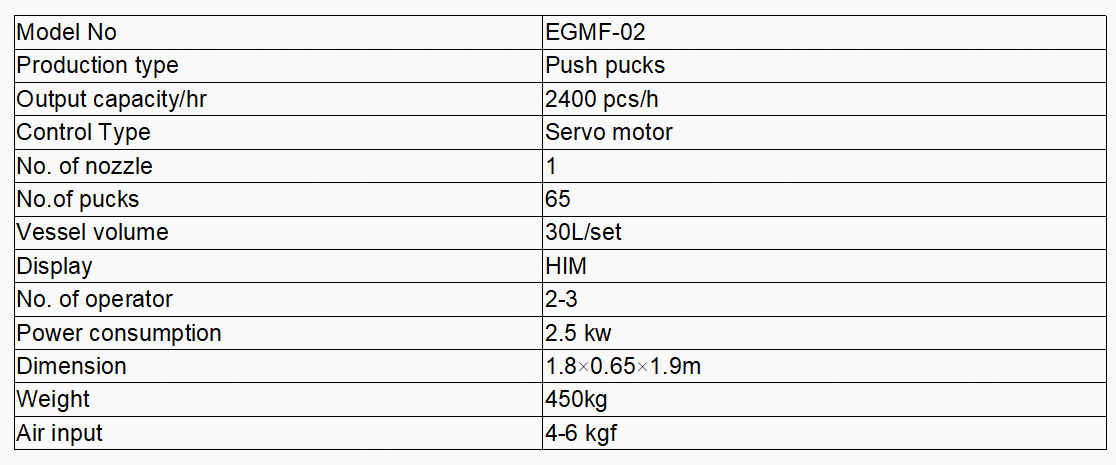

Mascara lipgloss filling machine Puck holder(Optional)

.POM materials,customized as bottle shape and size

Mascara lipgloss filling machine Capacity

.35-40pcs/min

Push table,65 puck holder Sensor check,no bottle no filling Servo motor filling,filling speed and volume adjustable

Plug pressing by air cylinder Servo motor capping,capping speed and torque adjustable Pressure plate inside of filling tank

60L pressure tank to put in ground Auto picking up finished products and put into output conveyor

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Free sample for Silicone Lipstick Mold Filling Production Line - Mascara Lipgloss Filling Machine – Eugeng , The product will supply to all over the world, such as: Bangalore, Ethiopia, Munich, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.