Hot New Products Hot Liquid Cooling Machine - Automatic Tunnel Freezer – Eugeng

Hot New Products Hot Liquid Cooling Machine - Automatic Tunnel Freezer – Eugeng Detail:

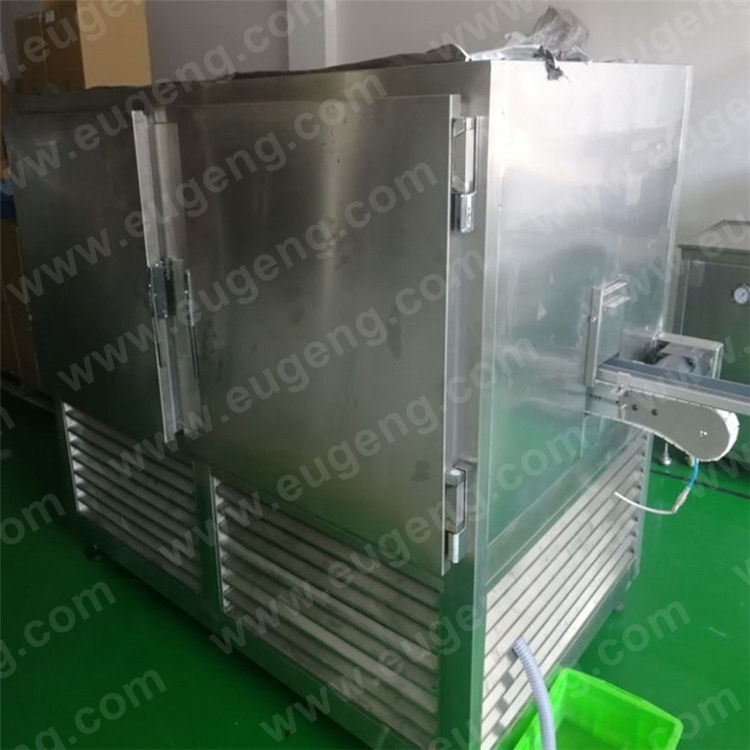

Model EGCT-5P is an automatic tunnel freezer cooling machine designed for the production of hot filling/pouring,such as lipstick,lip balm,wax and so on.

. Design for two tunnel with 2-4 station(option) and frost moving

.Stainless steel 304 frame

.Temp control by digital T.I.C

.Conveyor speed and cooling temp controlled according to the type of product

Cooling tunnel with 5 conveyors inside , with blowing cooling air form top .

. The guider on conveyor need adjustment for different size stick

. Temp control by digital T.I.C

. Min temp is -20°C, start and stop temp is adjustment

. Defrost time is adjustment

. Conveyor speed can be adjustment

. Stainless steel 304 frame with foam in the jacket

. Electric power: 240V Single phase 50/60HZ, 5000W

Component :

Refrigeration systems

. France Danfoss,Meter Danfoss

. Fan:China KUB,Controller:China KI&BNT

|

Voltage |

AC220V/50Hz |

|

Weight |

300kg |

|

Body material |

SUS304 |

|

Dimensions |

2500*1045*1450 |

|

Temp range |

0~-20°C |

|

Machine size |

1200*2000mm |

Can be customized according to actual needs.

Model with big size as below for reference.

Product detail pictures:

Related Product Guide:

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Hot New Products Hot Liquid Cooling Machine - Automatic Tunnel Freezer – Eugeng , The product will supply to all over the world, such as: Estonia, Lisbon, Las Vegas, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!