Hot Selling for Cosmetic Powder Mixing Machine - Baked Powder Production Line – Eugeng

Hot Selling for Cosmetic Powder Mixing Machine - Baked Powder Production Line – Eugeng Detail:

Baked powder mixing machine for mixing wet powder raw material firstly.

Target product

bake powder raw material

bake powder raw material

baked eye shadow

Capacity 20kg

Feature

1 set 20L mixing tank

Mixing speed can be adjustable

Mixer scrapper easily take off and re assembly

CW time and CCW time is adjustable

Tank can 90 degree open for discharge easily

Manul mixing optional according to request

Standard Specifications

| Model No. | EGBM-20 |

| Production type | MIixer |

| Output capacity/hr | 20kg/tank |

| Power consumption | 1.5kw |

| Dimension | 0.8×0.55×1.35m |

| Weight | 160kgs |

Machine Detail As Following Photo

Operation easily

Mixer speed is adjustable

Mixer scrapper easilytake off for cleaning

SUS304 stainess steel

Baked powder mixing machine You tube Video link

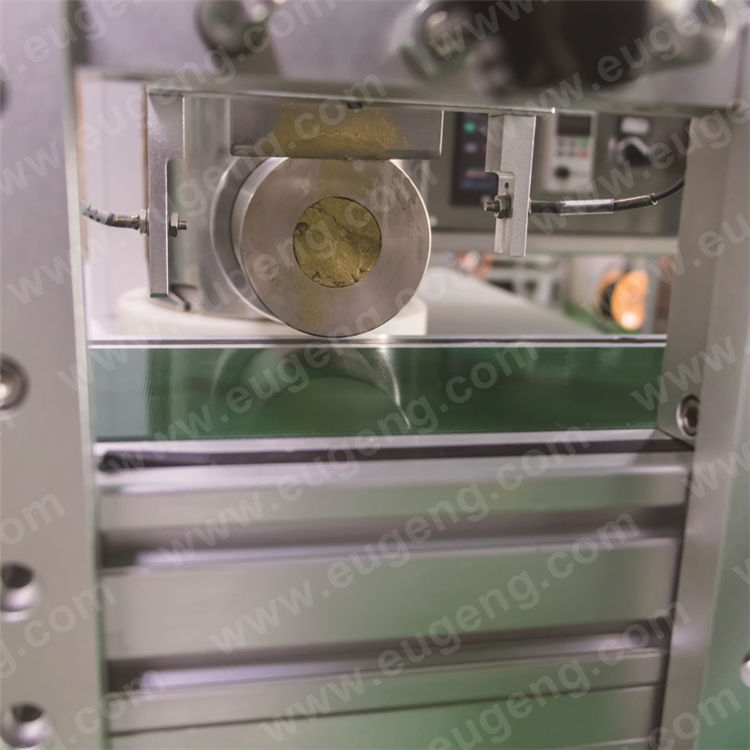

Baked powder extrusion machine after mixing

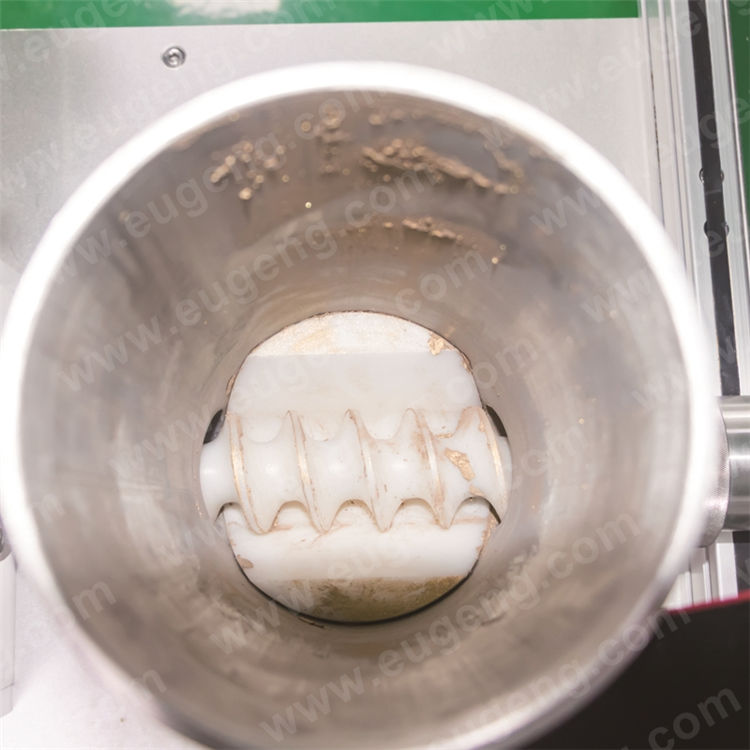

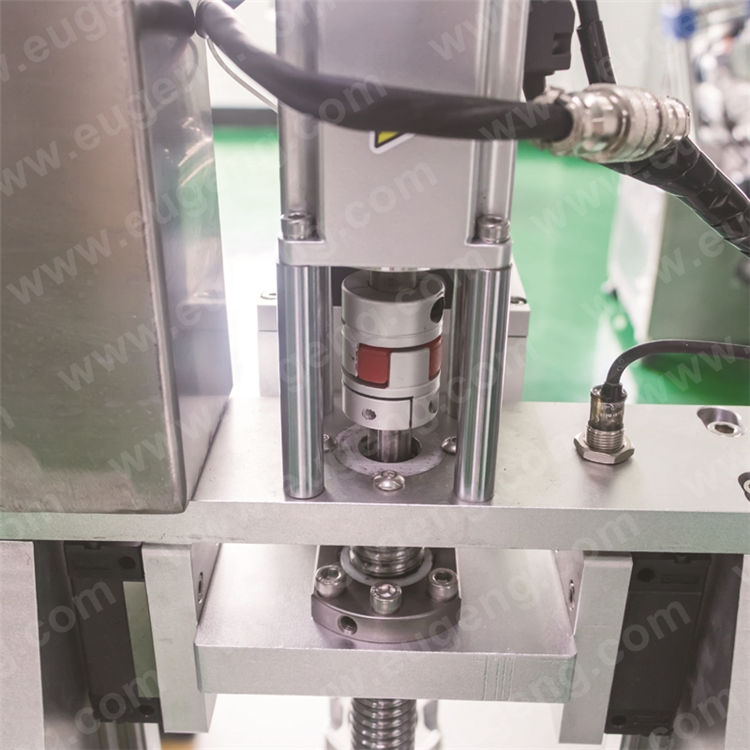

Mold Extrusion nozzle and screw

Capacity 30-35pcs/min

Feature

1 set 10L tank

Screw from back side and pressing from top

Sensor control the extrusion powder length, and it can be adjusted so that control the powder weight Automatic cutting

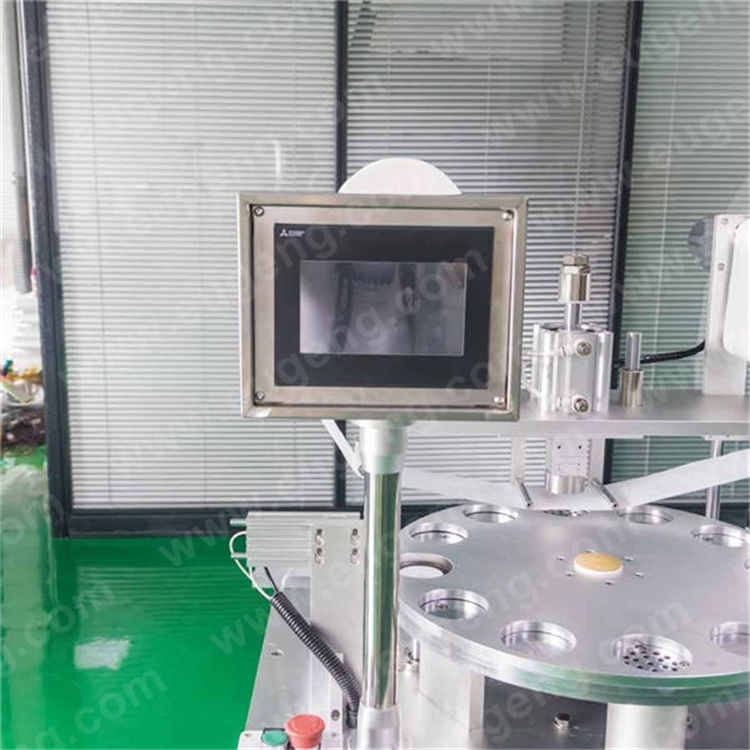

3 Type working model for felixable optional Operation with touch screen

Standard Specifications

| Model No. | EGBE-01 |

| Production type | Extrusion |

| Output capacity/hr | 1800-2100pcs |

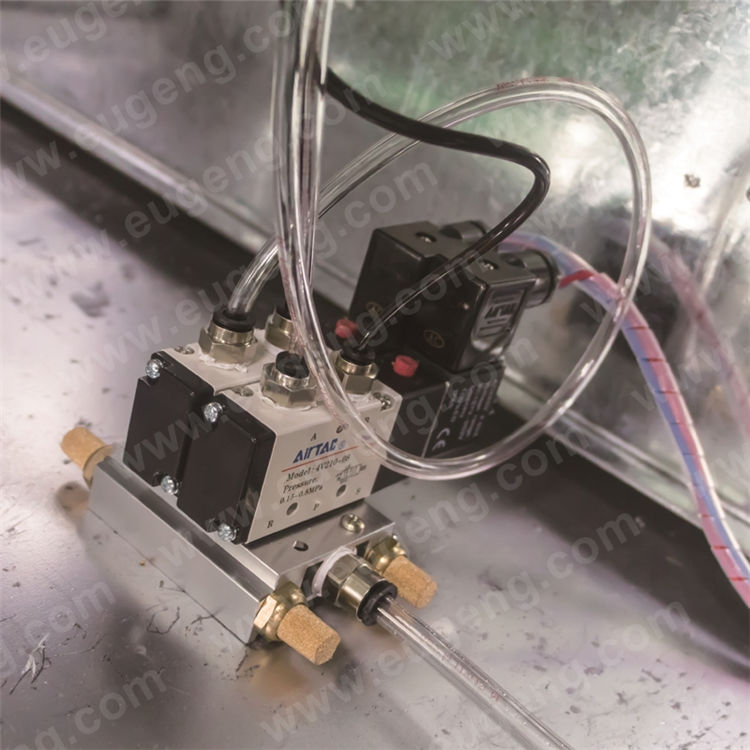

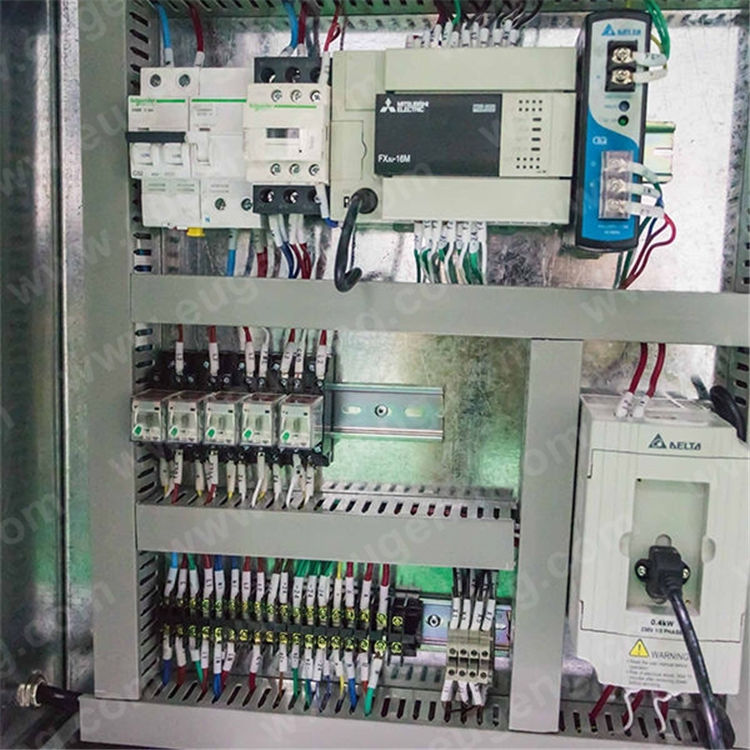

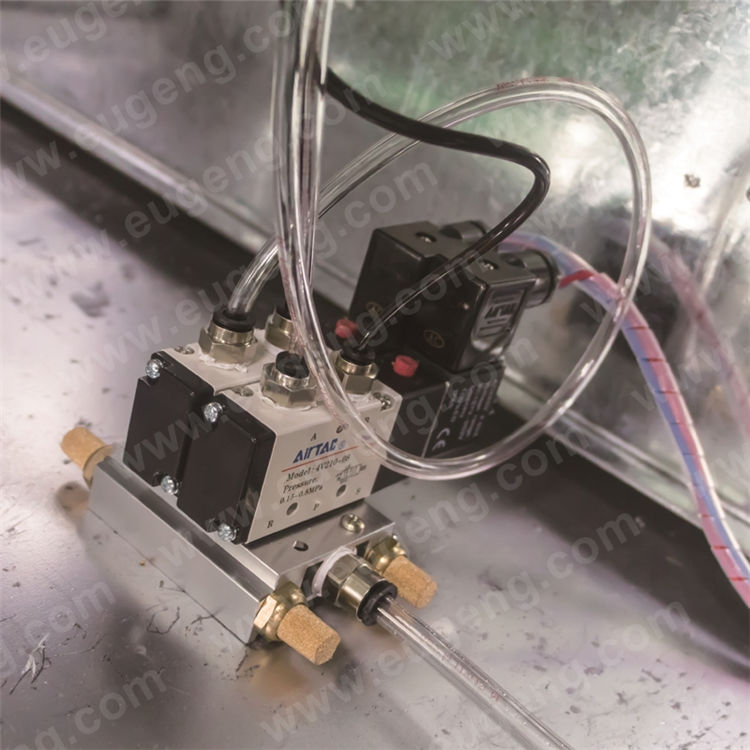

| Control Type | Motor & Air cylinder |

| No. of nozzle | 1 |

| Vessel volume | 10L/set |

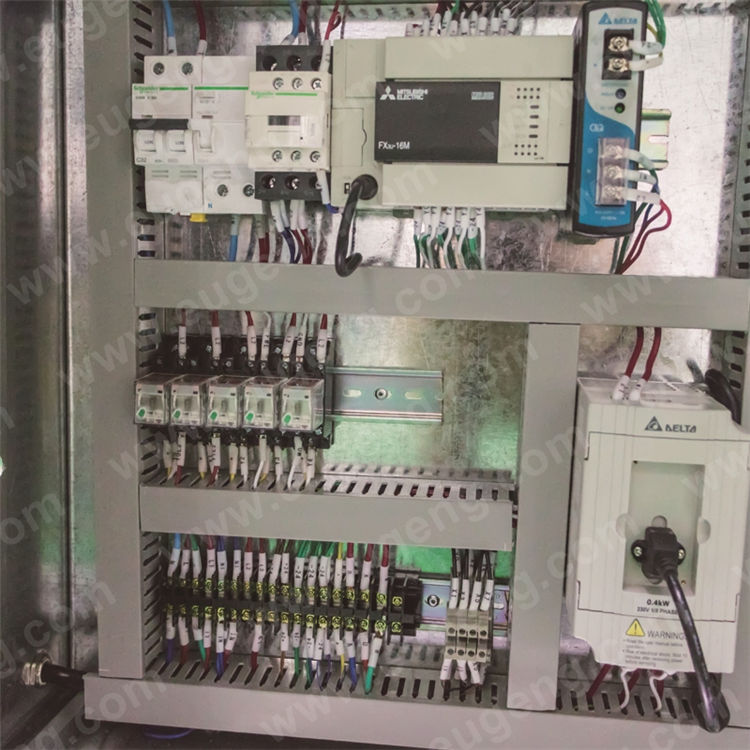

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 2 kw |

| Dimension | 1.2×0.8×1.75m |

| Weight | 250kgs |

| Air input | 4-6 kgf |

Machine Detail As Following Photo

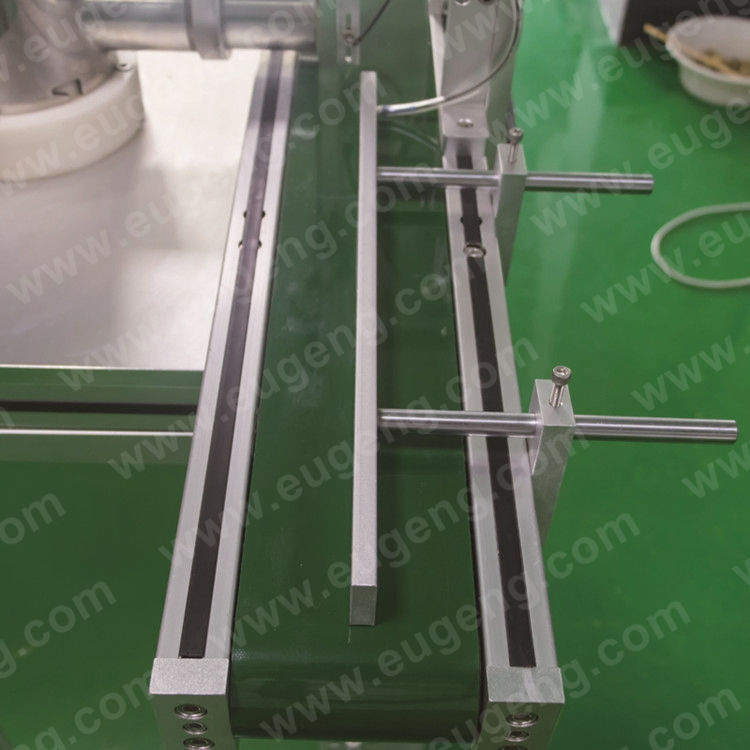

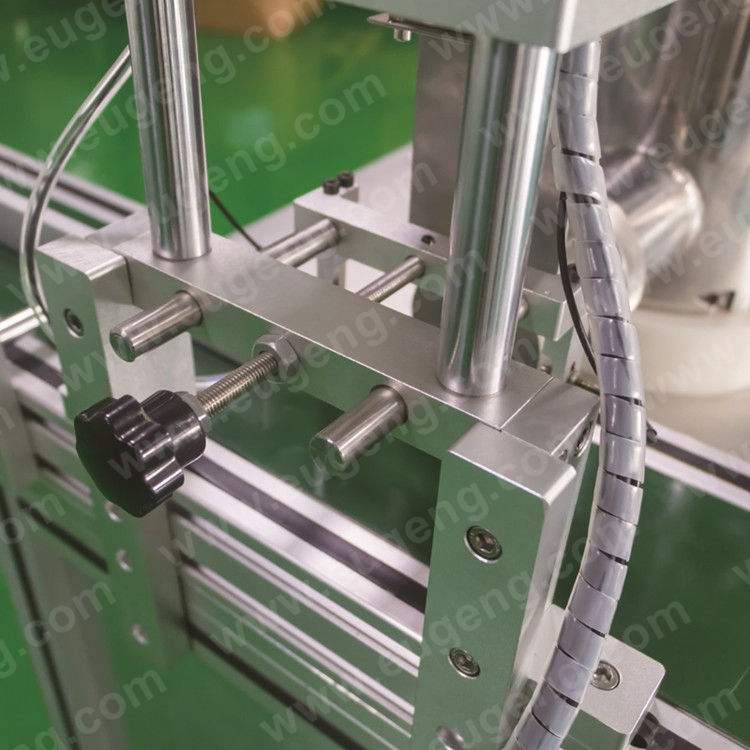

Guider can be adjusted

Cutting knife

Tank

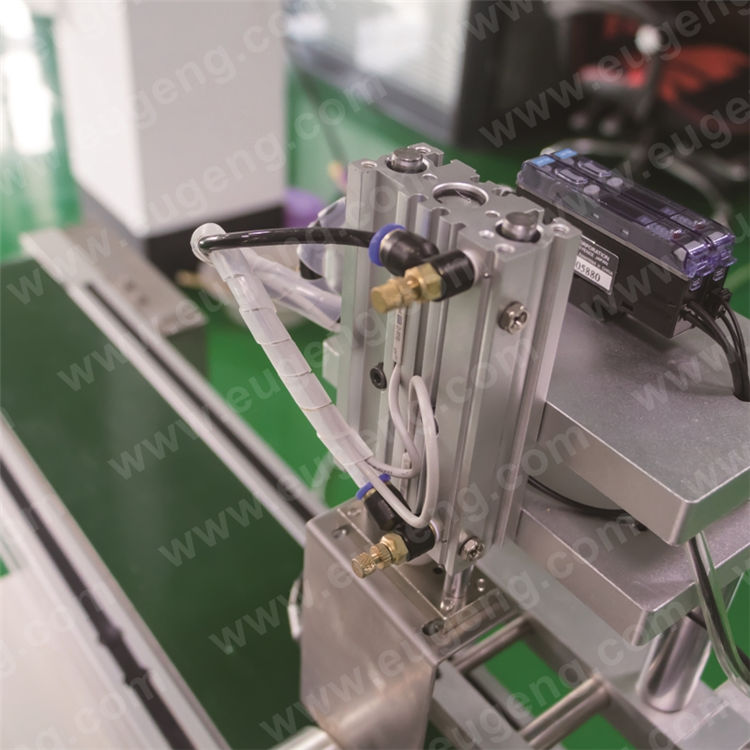

Keyence sensor for easy adjustment

Extrusion powder weight adjusted

Foot switch

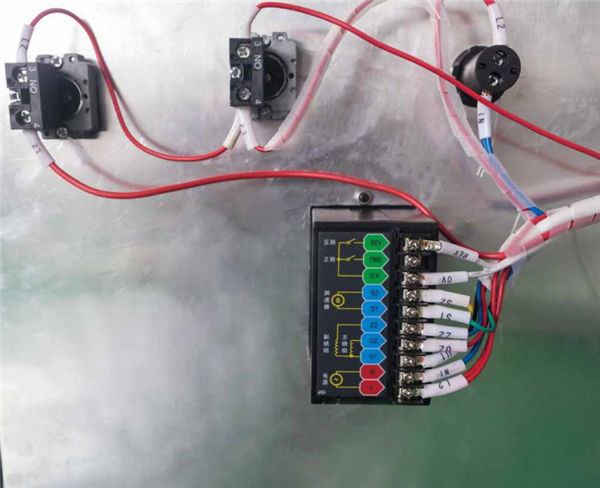

Touch screen operation

Bulk press from top

Extrusion nozzle

Baked powder extrusion machine Youtube Video link

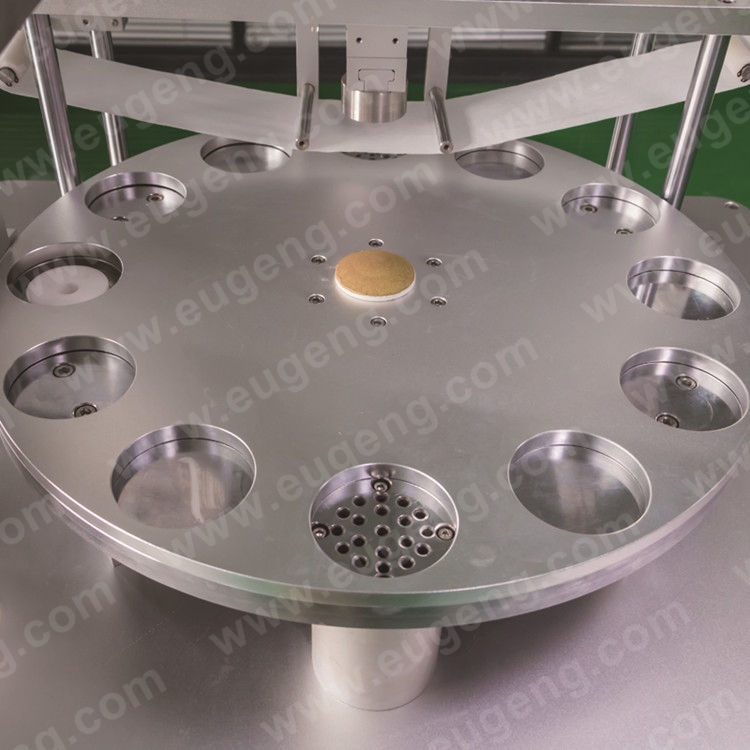

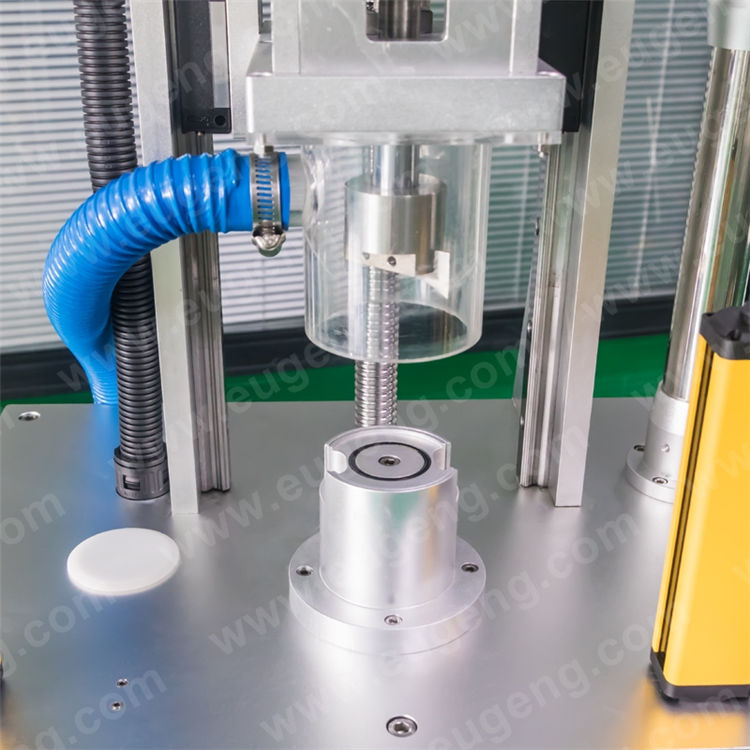

Baked powder pressing machine after extrusion. Controlled by air cylinder.

Mold Pucks according to different godet size

Capacity 12-15pcs/min

Feature

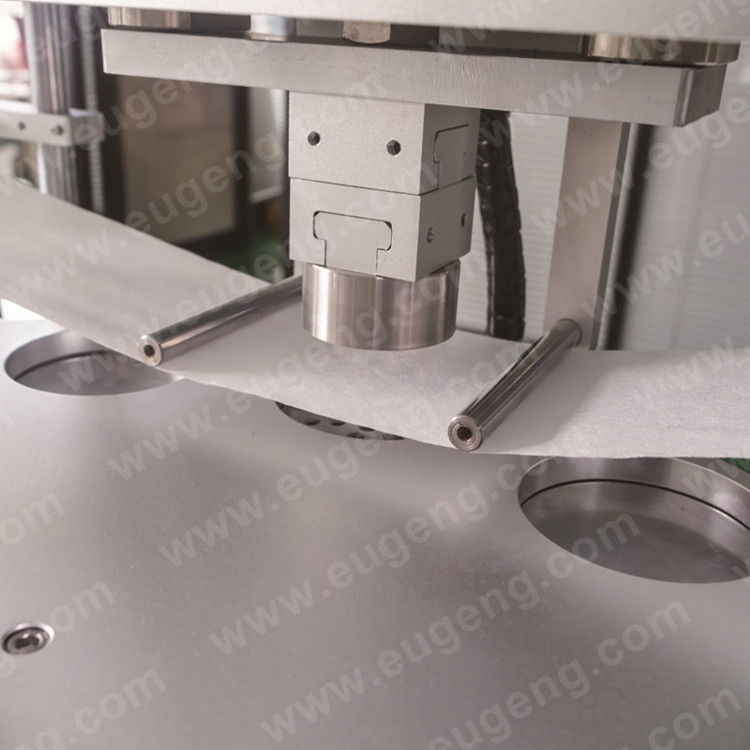

Rotary working table

Powder press with air cylinder, pressuer can be adjustable

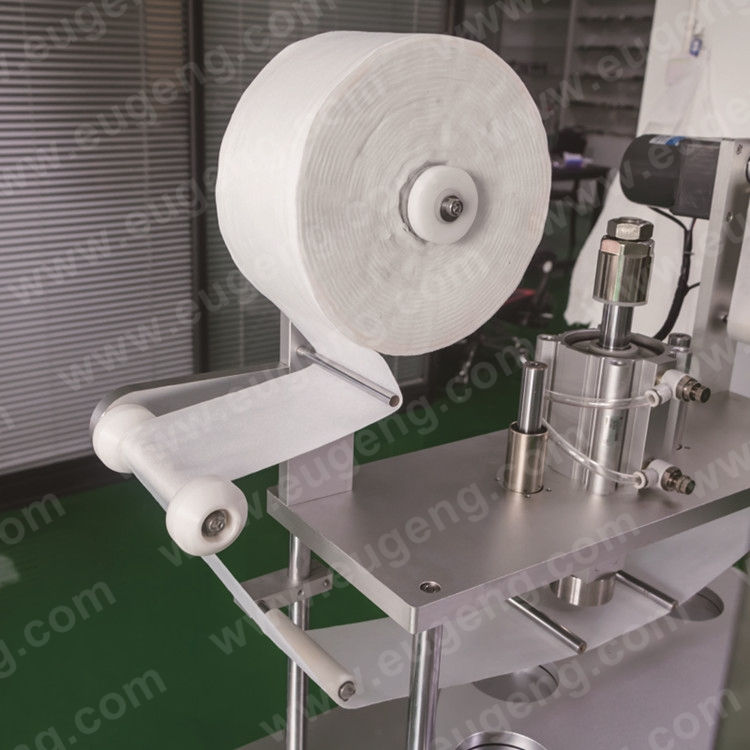

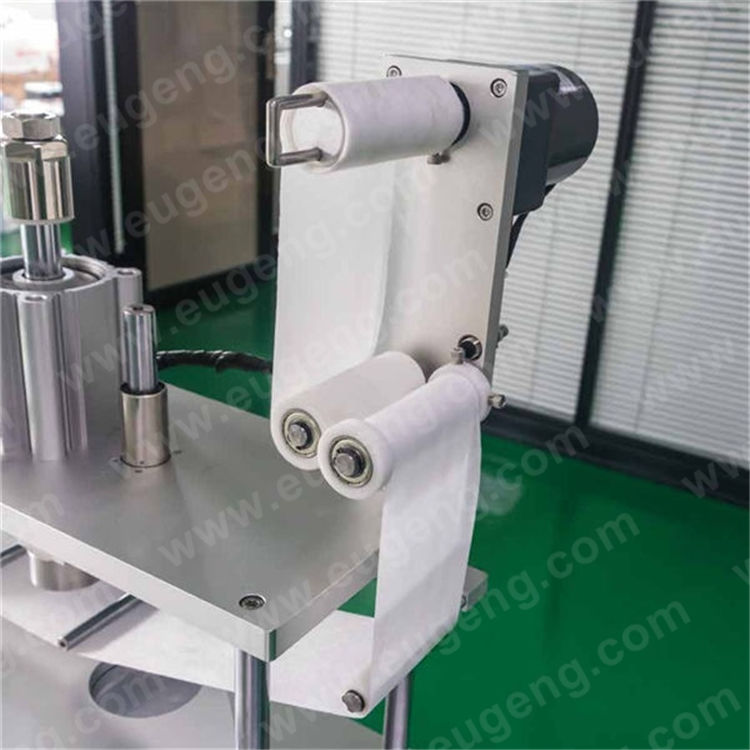

Automatic winding

Pressing time can set with once or twice

Automatic discharge

Vacuum collection powder Touch screen control system

Standard Specifications

| Model No. | EGBP-01 |

| Production type | Rotary |

| Output capacity/hr | 720-900pcs |

| Control Type | Air cylinder |

| No. of pressing head | 1 |

| No.of cavities | 12 |

| No. of operator | 1 |

| Power consumption | 0.75kw |

| Dimension | 1.2×0.8×1.65m |

| Weight | 3 50kgs |

| Air input | 4-6 kgf |

Machine Detail As Following Photo

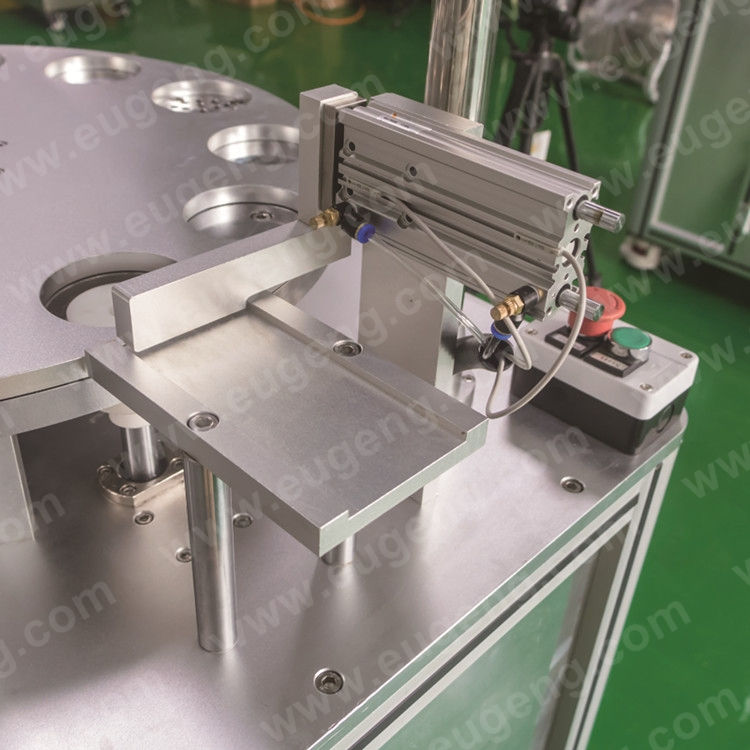

Turntable

Discharge

Winding

Air cylinder pressing

Different godet need change different pressing head

Fabic size can be adjustabel

Touch screen operation panel

Emergency

Speed controller

Baked powder press machine Youtube Video link

Baked powder baking oven after pressing

Capacity 1500pcs /cart

Feature

Aie dry baking with electric heating

Staines steel 304 inner frame

Max temp 300°C

Baking temp can be adjustable

Air blowing flowing can be adjustable

Machine Detail As Following Photo

Carts with wooden tray

Inner side og bake oven

Baking with crat

Baked powder baking oven Youtube Video link

Baked powder scrapping machine for treating surface of pressed powder after baking.

Make surface smooth and easily taken down for makeup.

Mold Scrapping knife& godet holder

Capacity 12-15pcs/min

Feature

Single holder for ceramic godet with vacuum fixed

Servo motor control knife moving up&down speed

Scrapping speed can be adjusted

Vacuum for collection powder make sure cleaning

Safety sensor protect operator hand cutting Touch screen operation

Standard Specifications

| Model No. | EGBS-01 |

| Production type | Manual |

| Output capacity/hr | 720-900 pcs |

| Control Type | Servo motor |

| No. of knife | 1 |

| No. of holder | 1 |

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 0.75kw |

| Dimension | 0.65×0.85×1.4m |

| Weight | 150kgs |

| Air input | 4-6 kgf |

Machine Detail As Following Photo

Turntable

Servo motor control up&down speed

Scrapping knife height can be adjusted

Safety sensor protect operator hand cutting

Emergency

Vacuum for collection the dust powder

PLC MITSUBISHI

Baked powder scrapping machine Youtube Video link

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Hot Selling for Cosmetic Powder Mixing Machine - Baked Powder Production Line – Eugeng , The product will supply to all over the world, such as: Detroit, Bangladesh, Paraguay, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!