Welcome to our websites!

Nail Polish Filling And Capping Machine

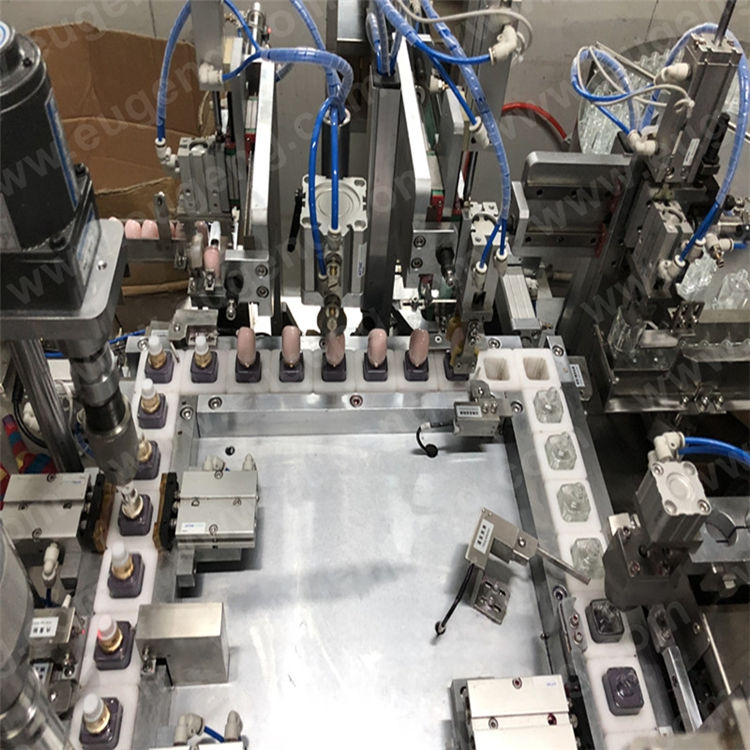

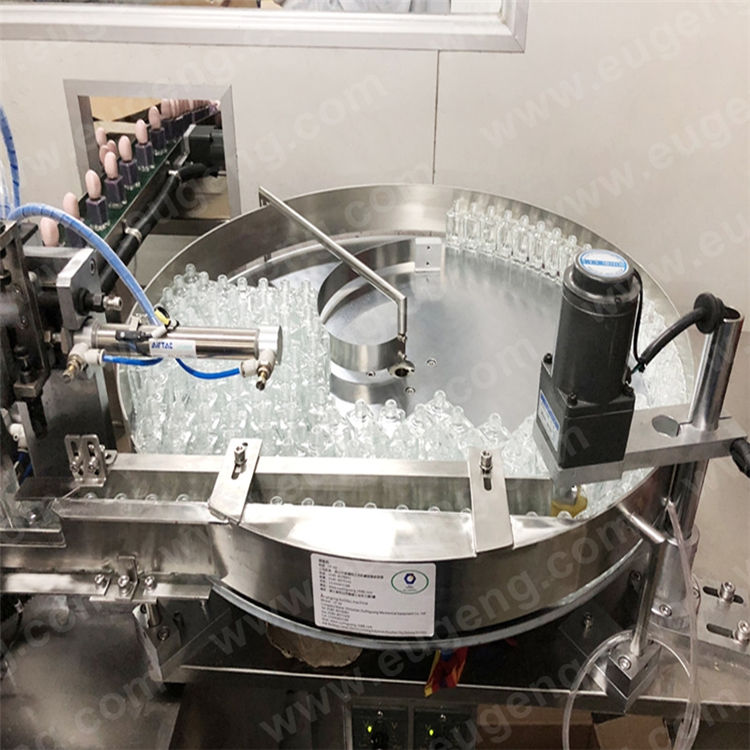

Indexing turn table with 35 bottlers holder, 10 working station

1 set of 60 L pressure tank

Automatic feeding bottles,fill balls ,loading brush,and cap loading and capping

1 set filling balls unit with automatic by cylinder,and fill 0 / 1 / 2 balls once

Vacuum or piston filling structure for optional

If material with more big glitter ,Suggest use piston filling system

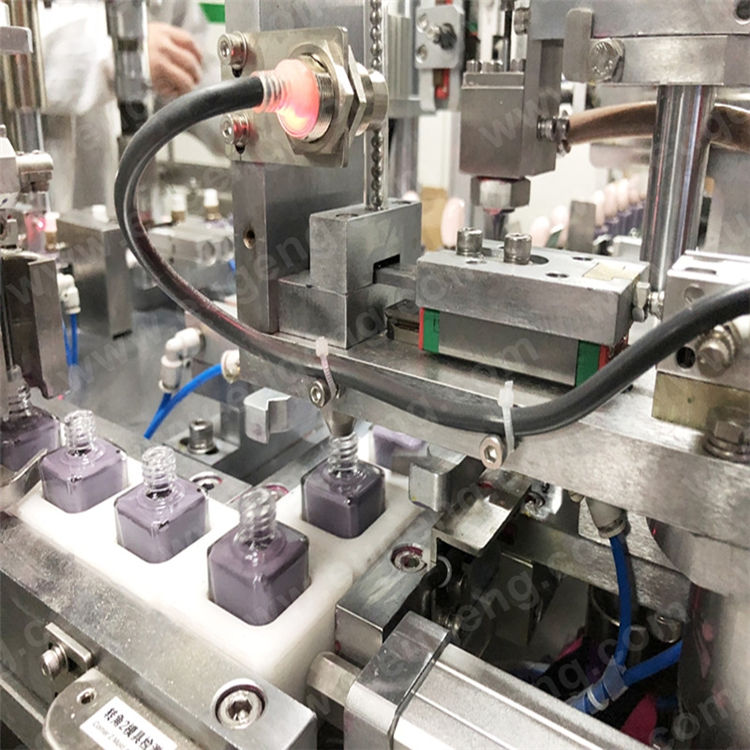

Cap tightening station tightens caps to correct torque by servo motor (you can set the torque through touch screen)

Automatic taking out finished products

nail polish filling and capping machine Capacity

30-35 bottles/min

nail polish filling and capping machine Mold

Nylon pucks (according to different bottle size)

| Model | EGNF-01A |

| Voltage | 220V 50Hz |

| Production type | Push type |

| Output capacity/hr | 1800-2100pcs |

| Control type | Air |

| No. Of nozzle | 1 |

| No. of working station | 35 |

| Vessel volume | 60L/set |

| Display | PLC |

| No. of operator | 0 |

| Power consumption | 2kw |

| Dimension | 1.5*1.8*1.6m |

| Weight | 450kgs |

| Air input | 4-6kgf |

| Optional | Pucks |

Automatic feeding bottles into machine

Automatic filling

Sensor for checking tubes,no tube, no filling

Automatic fill stainless ball

You put your bulk tank into our pressure tank directly

Automatic loading brush

Vibrator feeding the caps

Automatic loading cover cap

Loading inner caps and pre-screw

Screw capping, torques can be adjusted

Automatic take out the finished products

Electric components brand list

| Item | Brand | Remark |

| Touch screen | Mitsubishi | Japan |

| Switch | Schneider | Germany |

| Pneumatic component | SMC | China |

| Inverter | Panasonic | Japan |

| PLC | Mitsubishi | Japan |

| Relay | Omron | Japan |

| Servo motor | Panasonic | Japan |

| Conveyor&mixingmotor | Zhongda | Taiwan |

Write your message here and send it to us