OEM Manufacturer Cosmetic Jar Powder Filling And Capping Machine - Compact Powder Pressing Machine – Eugeng

OEM Manufacturer Cosmetic Jar Powder Filling And Capping Machine - Compact Powder Pressing Machine – Eugeng Detail:

Model EGCP-06 compact powder pressing machine is an semi-automatic compact powder pressing machine design for the production of compact powder , eyeshadow,two-way cake,cosmetic powder foundation and blush.Suitable for both square shape and round shape godets.Equipped with vacuum dust powder collection system to ensure cleaning surface of pressed powder.

Compact powder pressing machine features

● Hydraulic ram press unit and digital pressure control unit

● Main pressing by back side pressing head

● Multi-time pressing :Max. 3 times

● Powder collecting barrel for recycling

● Automatic winding

Compact powder pressing machine Application

Used for making compact face powder,two-way cake,eyeshadow,blush,powder foundation

Compact powder pressing machine Mold customized

Pressing mold (according to the godet size)

Compact powder pressing machine Capacity

12-18pcs/min(according to different size)

Eyeshadow

Blush

Compact powder

|

Model |

EGCP-06 |

|

Production type |

Liner type |

|

Capacity |

720-1080pcs/h |

|

Control type |

hydraulic |

|

Powder hopper |

5kgs |

|

Display |

PLC |

|

No. of operator |

1 |

|

Power consumption |

3kw |

|

Dimension |

1.6*0.9*1.7m |

|

Weight |

800kgs |

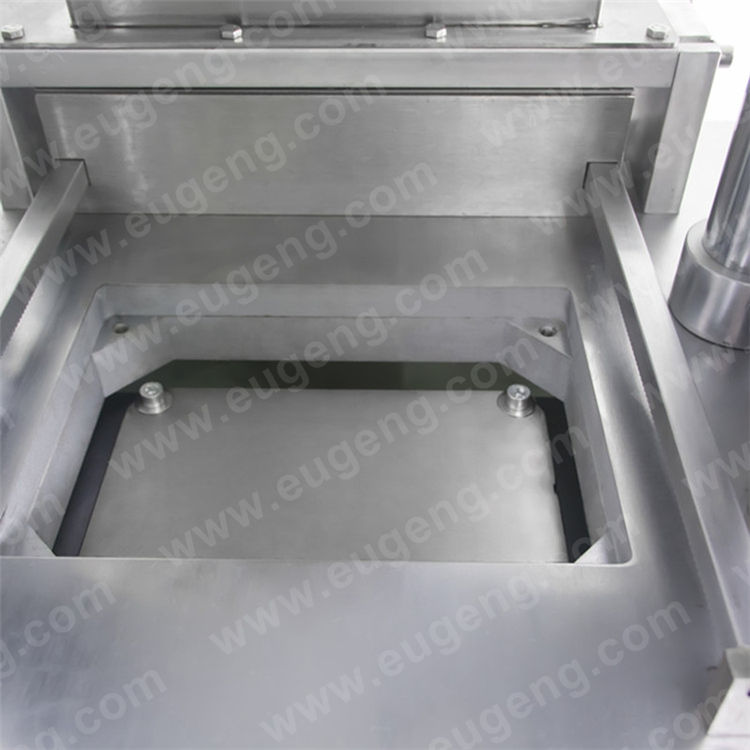

Working table Photoelectric safety

Easy change molds designing

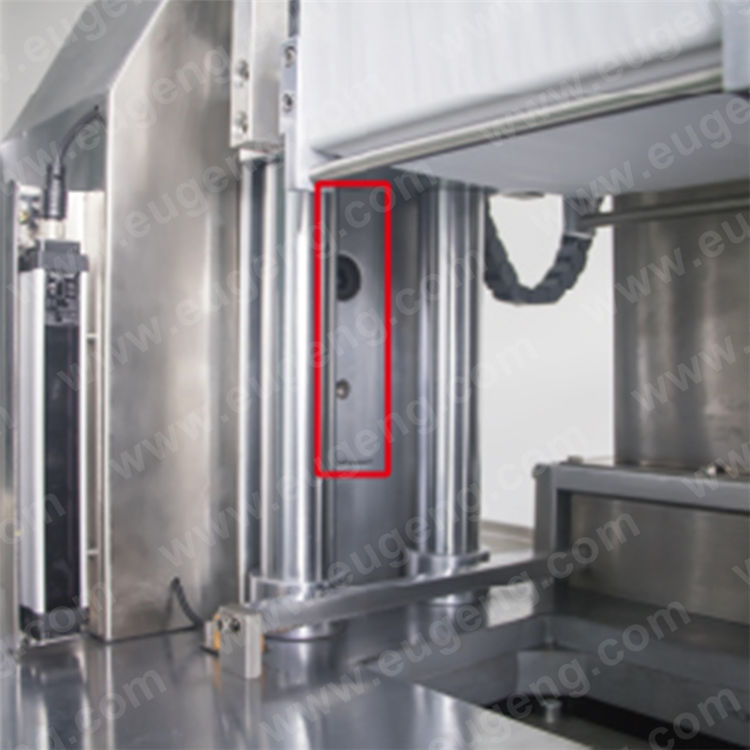

Top mold locking

Tray for collection powder under hopper

Mold locking with hydraulic cylinder

Hydraulic pump cooling system

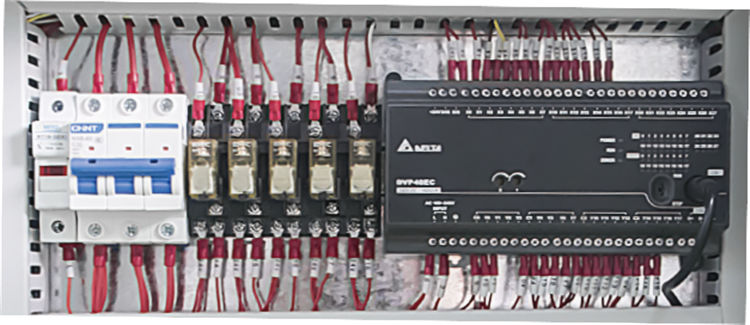

Hydraulic control system

Dust cleaning system

Fabric ribbon

PLC DELTA

Our factory(10+ years of industry experience); Overseas market layout(Customer group photo/Overseas market)

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for OEM Manufacturer Cosmetic Jar Powder Filling And Capping Machine - Compact Powder Pressing Machine – Eugeng , The product will supply to all over the world, such as: United Arab Emirates, Bangladesh, Thailand, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!