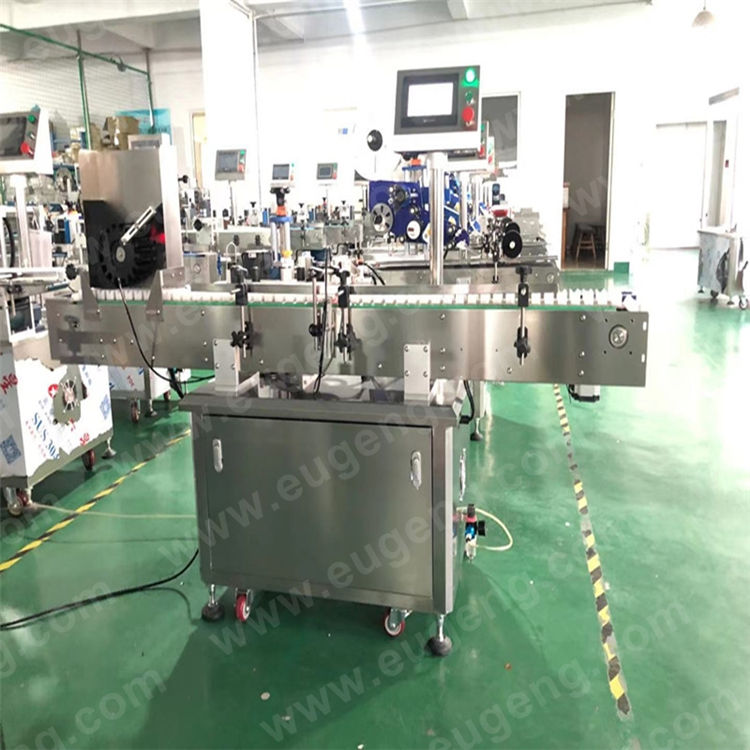

OEM Supply Wrap Around Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng

OEM Supply Wrap Around Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng Detail:

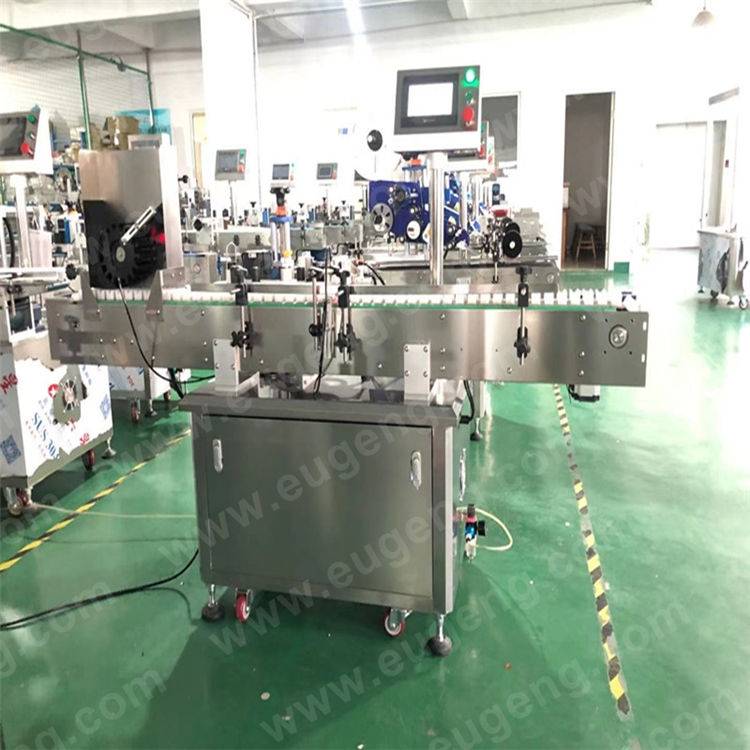

Model EGBL-600 horizontal bottom labeling machine is a semi-automatic horizontal labeling machine design for the production of slim round bottles,tube products,such as lip balm bottles,lip gloss bottles,lipstick bottles,mascara,eyeliner pen and so on.

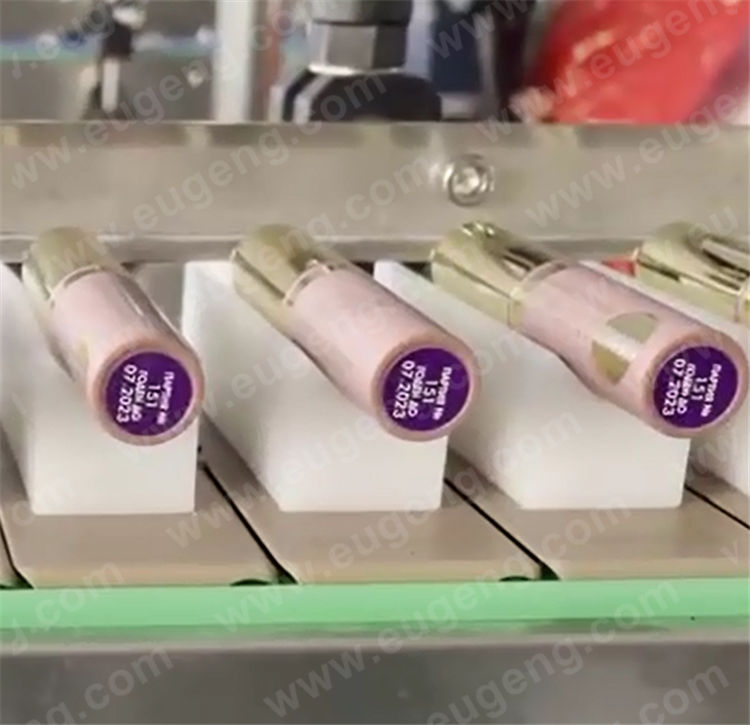

Mascara bottom labeling

Mascara bottom labeling

Lip gloss bottom labeling

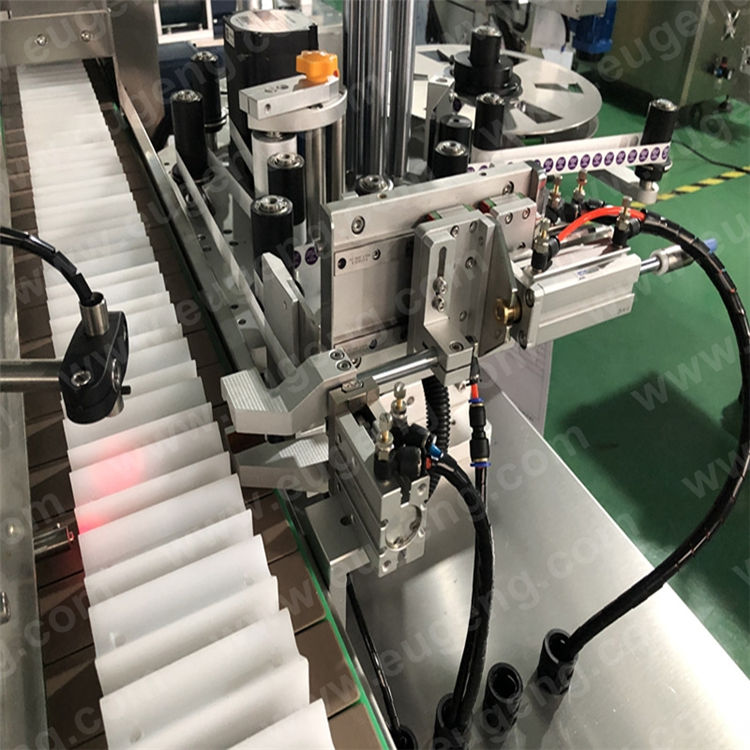

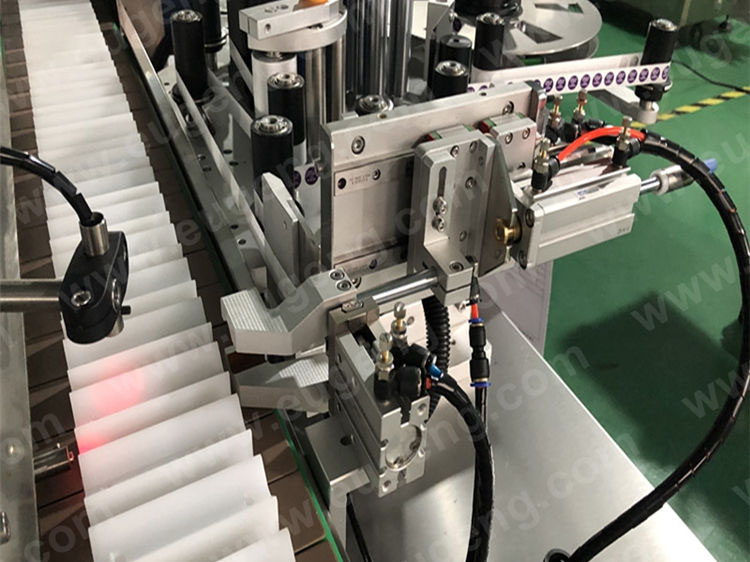

Automatic sensor check , no products, no labeling

Labeling Accuracy +/-1mm

Automatic roll label for prevent missing label

Labeling head X&Y position can be adjusted

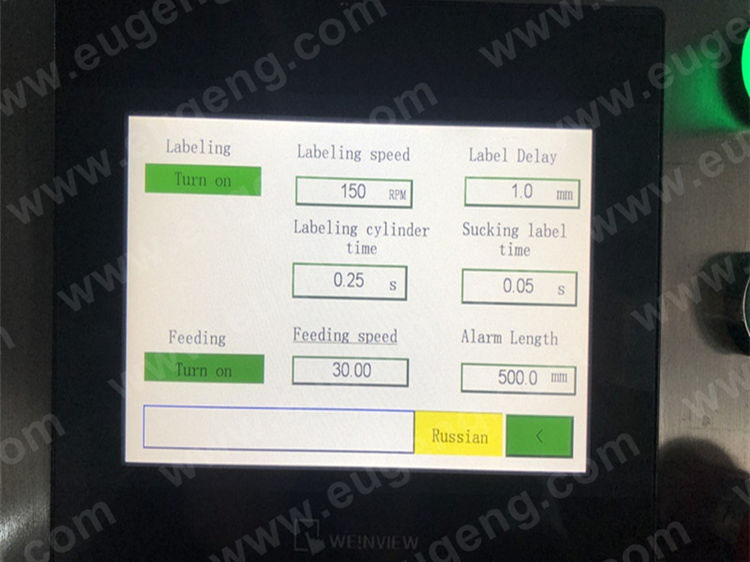

Touch screen operation

Equipped with counting function

Labeling speed,conveying speed and products feeding speed can be set on the touch screen

Label delay length and alarm length can be set on the touch screen

Labeling cylinder time and sucking label time can be set on the touch screen

Language can be customized as user’s language

Product positioning device ensures high labeling accuracy and also higher labeling speed

Horizontal bottom labeling machine Capacity

50-60pcs/min

Horizontal bottom labeling machine Optional

Transparent label sensor

Hot stamping label sensor

| Model | EGBL-600 |

| Production type | Liner type |

| Capacity | 50-60pcs/min |

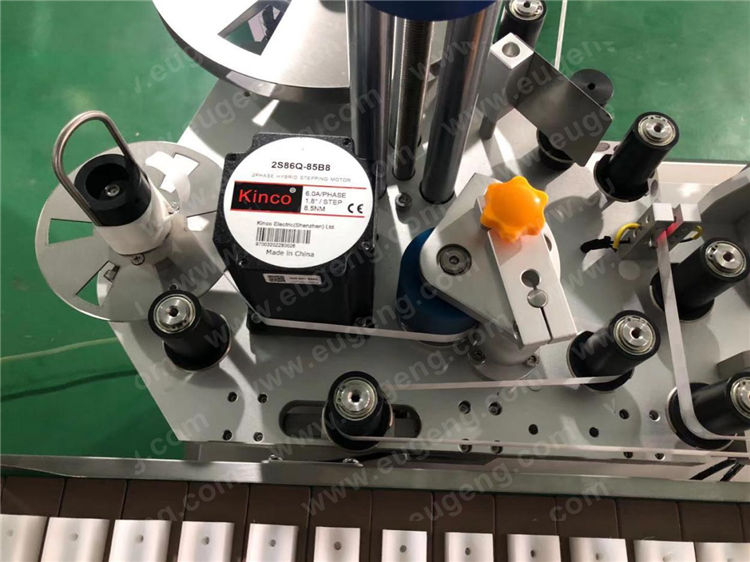

| Control type | stepper motor |

| Labeling accuracy | +/-1mm |

| Label size range | 10«width«120mm,length»20mm |

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 1kw |

| Dimension | 2100*850*1240mm |

| Weight | 350kgs |

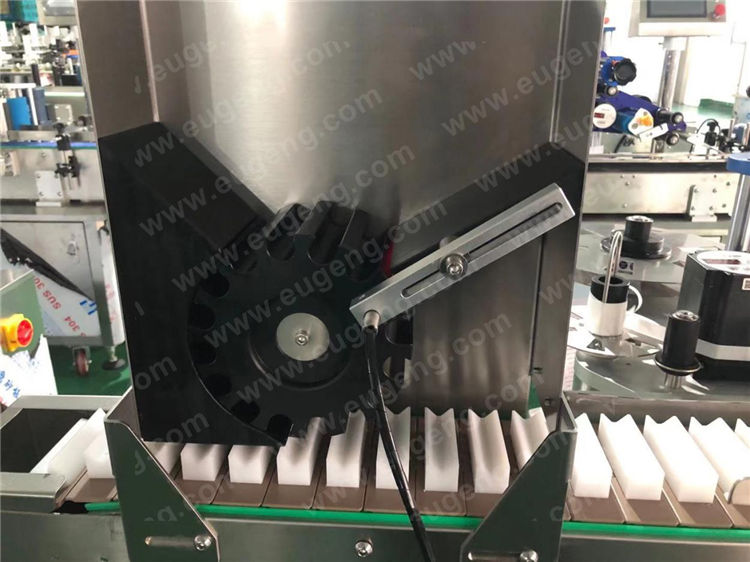

Bottles feeding hopper

Automatic check the label and correct the position

Product sensor

Labeling position can be adjusted

Stepper motor control labeling

Winding roller

PLC MITSUBISHI

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for OEM Supply Wrap Around Labeling Machine - Horizontal Bottom Labeling Machine – Eugeng , The product will supply to all over the world, such as: Plymouth, America, Dubai, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.