Professional China Automatic Loose Powder Filling Machine - Baked Powder Production Line – Eugeng

Professional China Automatic Loose Powder Filling Machine - Baked Powder Production Line – Eugeng Detail:

Model EGBM-20 is an automatic mixing ma- chine design for the production of baked powder raw material

Target product

bake powder raw material

bake powder raw material

baked eye shadow

Capacity 20kg

Feature

1 set 20L mixing tank

Mixing speed can be adjustable

Mixer scrapper easily take off and re assembly

CW time and CCW time is adjustable

Tank can 90 degree open for discharge easily

Manula mixing optional according to request

Standard Specifications

| Model No. | EGBM-20 |

| Production type | MIixer |

| Output capacity/hr | 20kg/tank |

| Power consumption | 1.5kw |

| Dimension | 0.8×0.55×1.35m |

| Weight | 160kgs |

Machine Detail As Following Photo

Operation easily

Mixer speed is adjustable

Mixer scrapper easilytake off for cleaning

SUS304 stainess steel

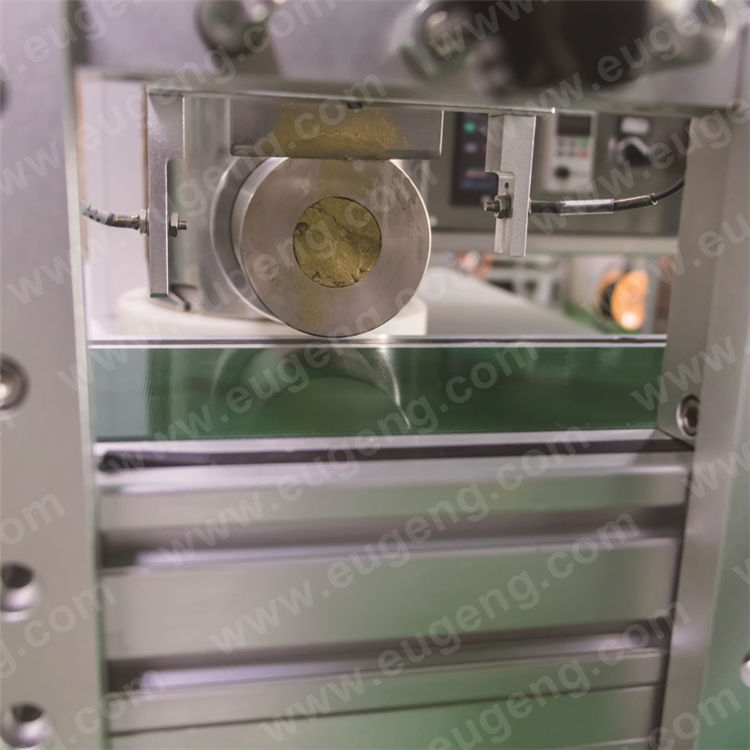

Model EGBE-01 is an semi-automatic extru- sion machine design for production of baked powder, blush & eye- shadow

Mold Extrusion nozzle and screw

Capacity 30-35pcs/min

Feature

1 set 10L tank

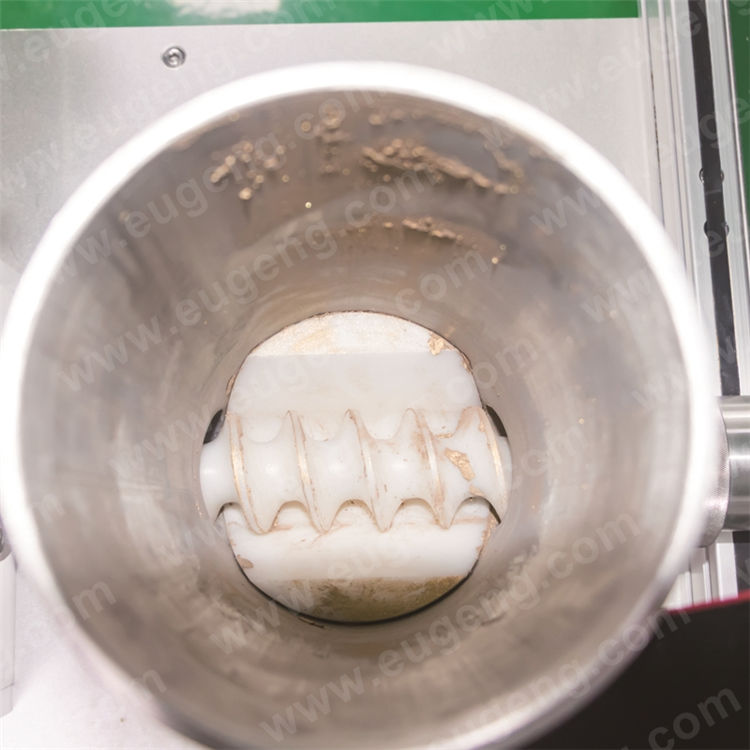

Screw from back side and pressing from top

Sensor control the extrusion powder length, and it can be adjusted so that control the powder weight Automatic cutting

3 Type working model for felixable optional Operation with touch screen

Standard Specifications

| Model No. | EGBE-01 |

| Production type | Extrusion |

| Output capacity/hr | 1800-2100pcs |

| Control Type | Motor & Air cylinder |

| No. of nozzle | 1 |

| Vessel volume | 10L/set |

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 2 kw |

| Dimension | 1.2×0.8×1.75m |

| Weight | 250kgs |

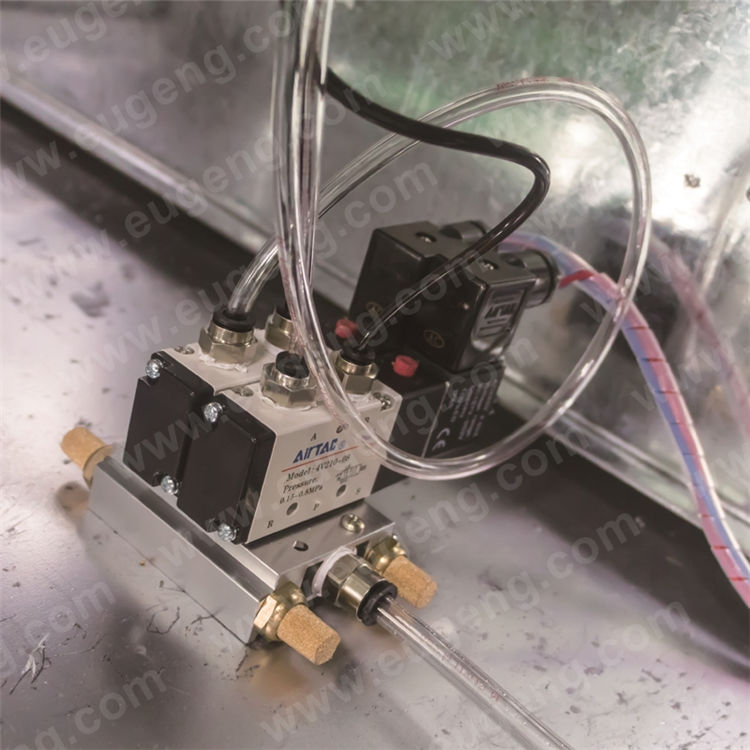

| Air input | 4-6 kgf |

Machine Detail As Following Photo

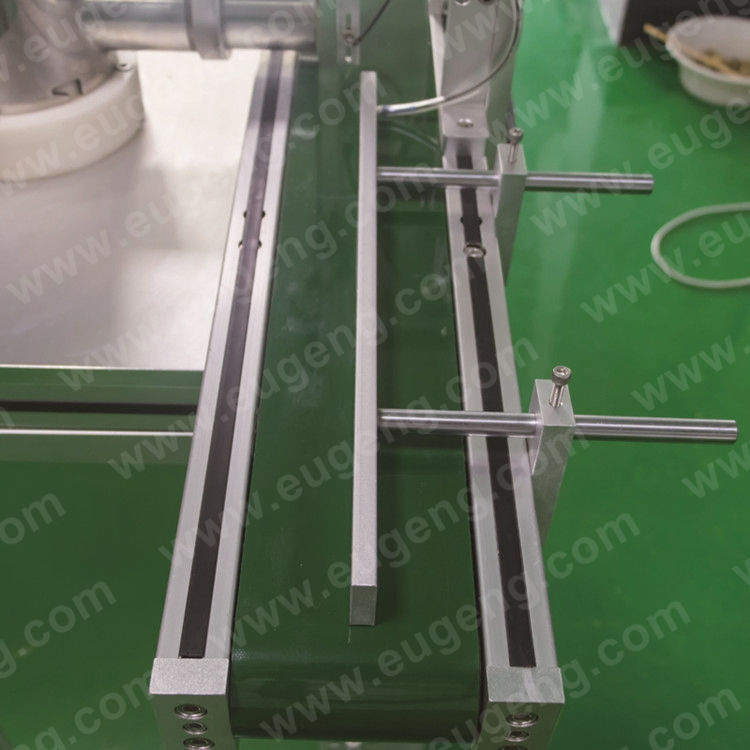

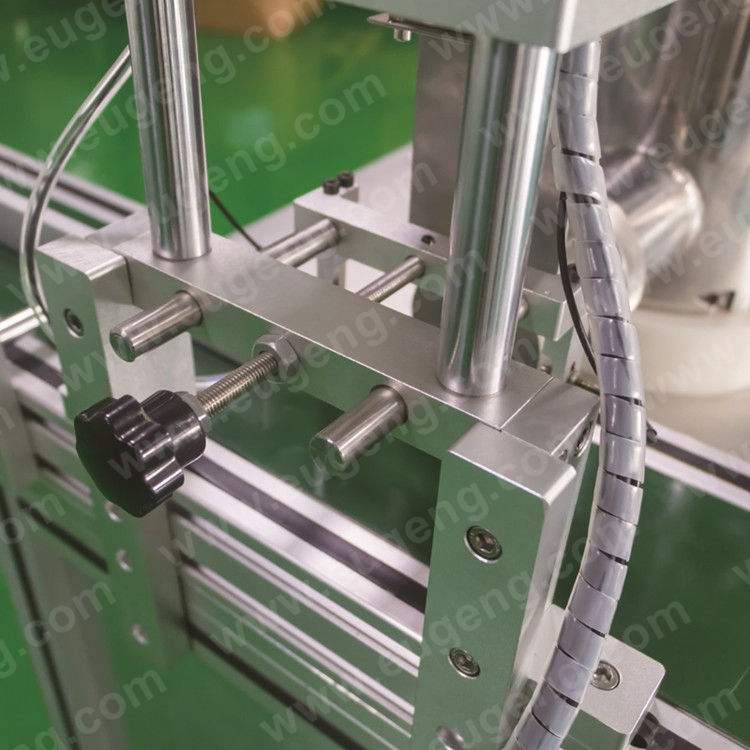

Guider can be adjusted

Cutting knife

Tank

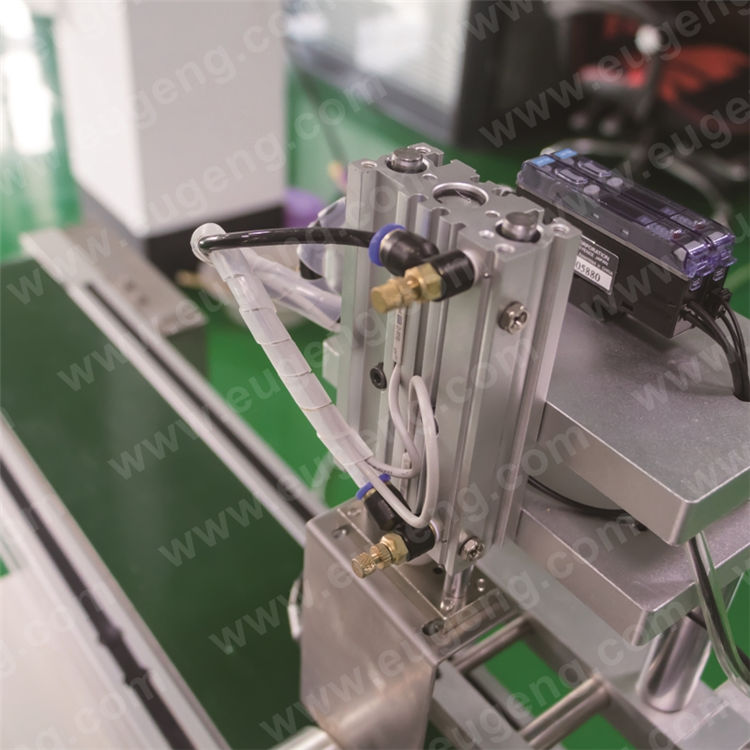

Keyence sensor for easy adjustment

Extrusion powder weight adjusted

Foot switch

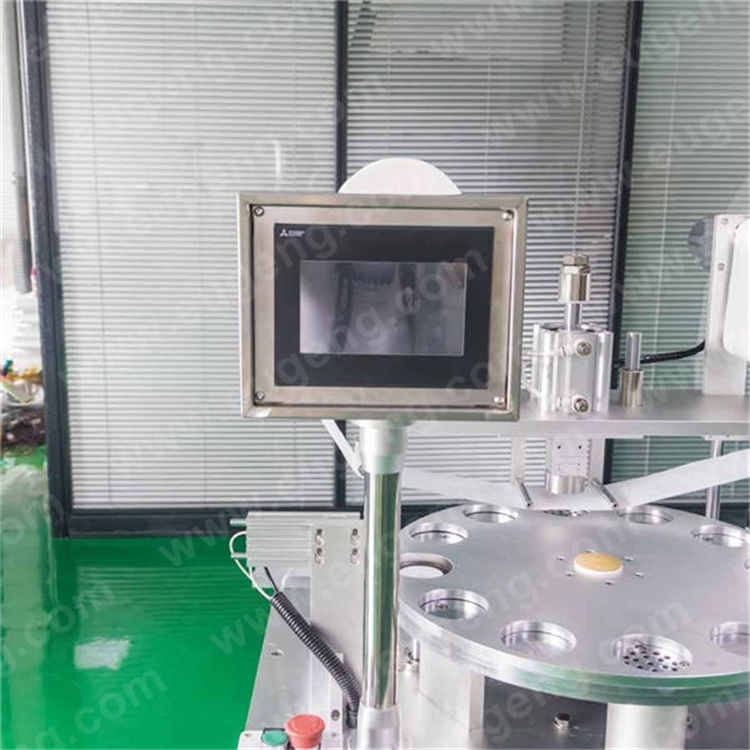

Touch screen operation

Bulk press from top

Extrusion nozzle

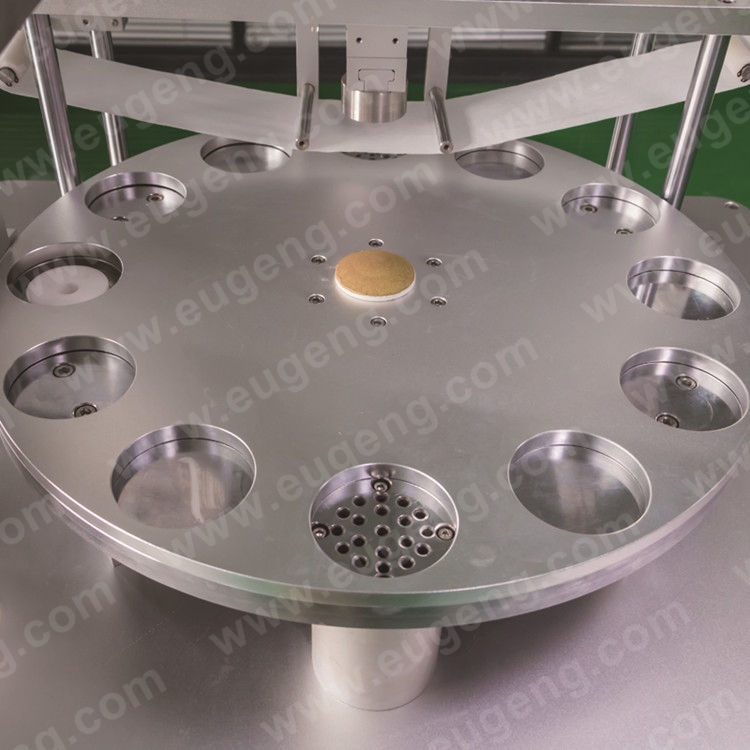

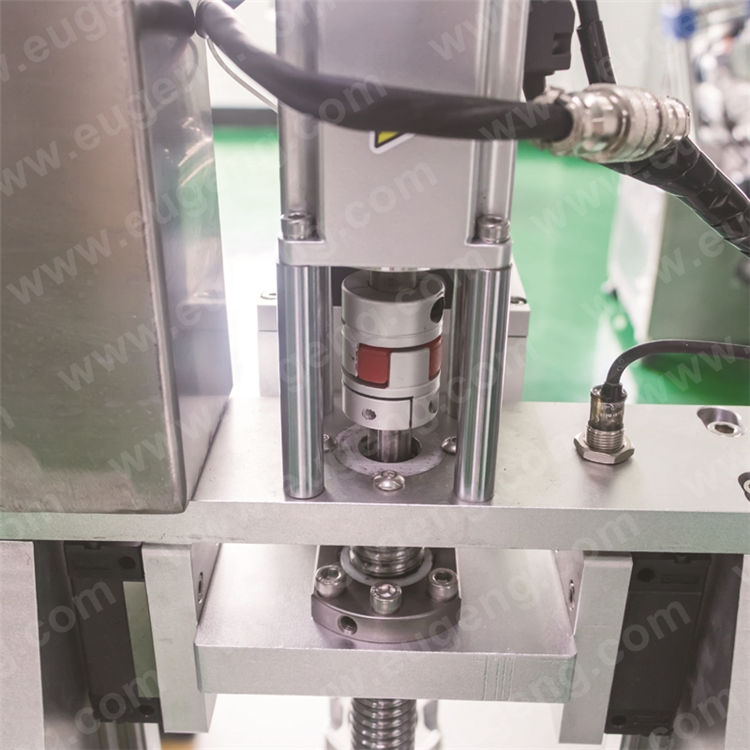

Model EGBP-01 is an semi-automatic powder pressing machine design for the produc- tion of baked powder ,blush and eyeshadow

Mold Pucks according to different godet size

Capacity 12-15pcs/min

Feature

Rotary working table

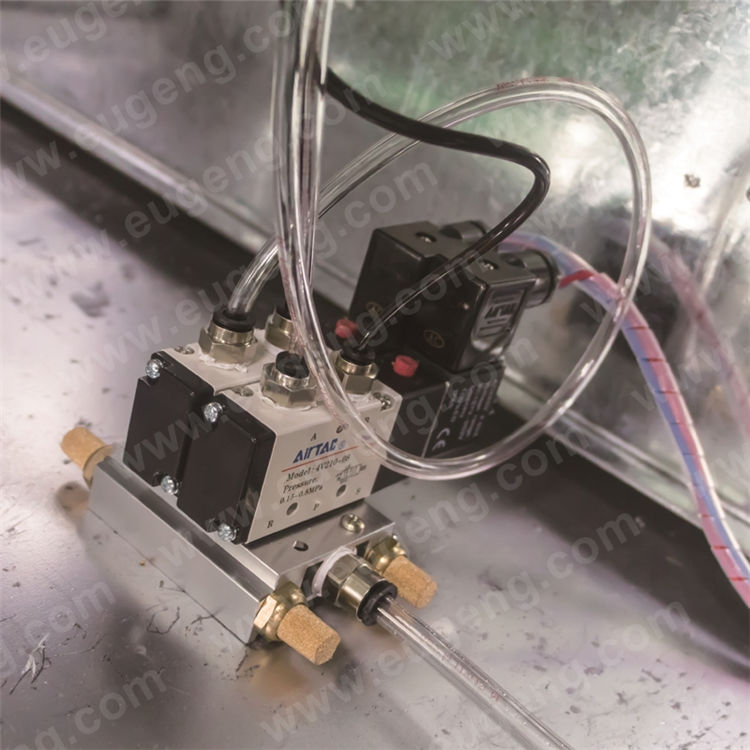

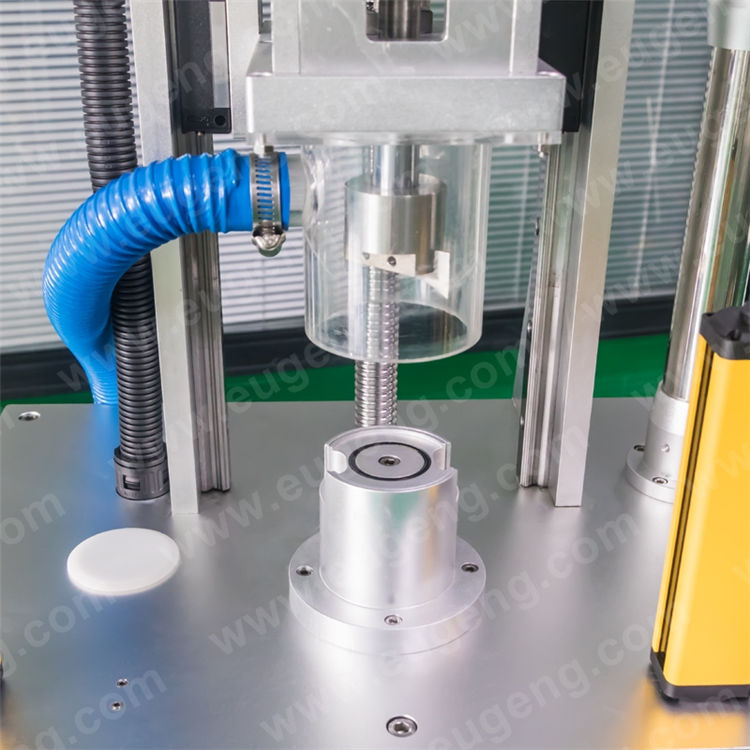

Powder press with air cylinder, pressuer can be adjustable

Automatic winding

Pressing time can set with once or twice

Automatic discharge

Vacuum collection powder Touch screen control system

Standard Specifications

| Model No. | EGBP-01 |

| Production type | Rotary |

| Output capacity/hr | 720-900pcs |

| Control Type | Air cylinder |

| No. of pressing head | 1 |

| No.of cavities | 12 |

| No. of operator | 1 |

| Power consumption | 0.75kw |

| Dimension | 1.2×0.8×1.65m |

| Weight | 3 50kgs |

| Air input | 4-6 kgf |

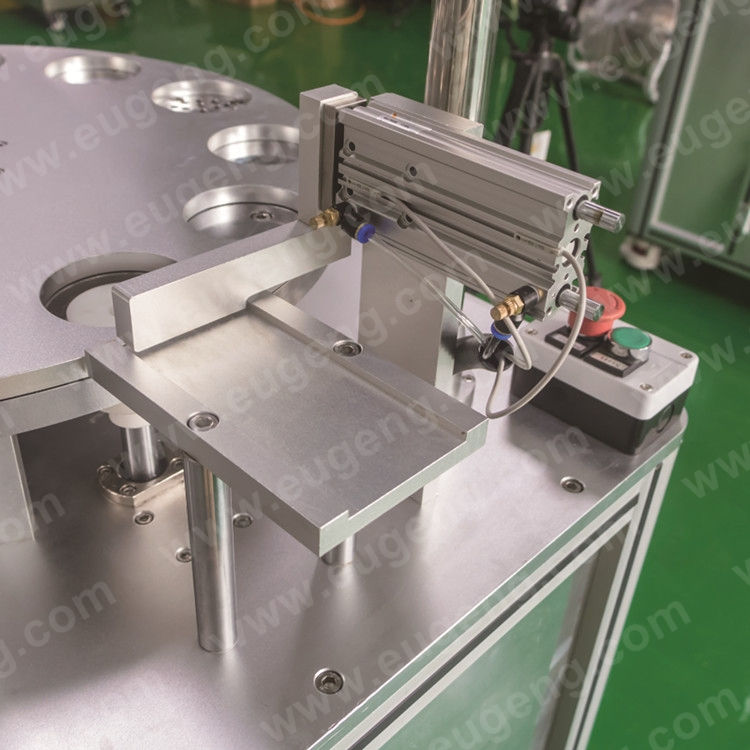

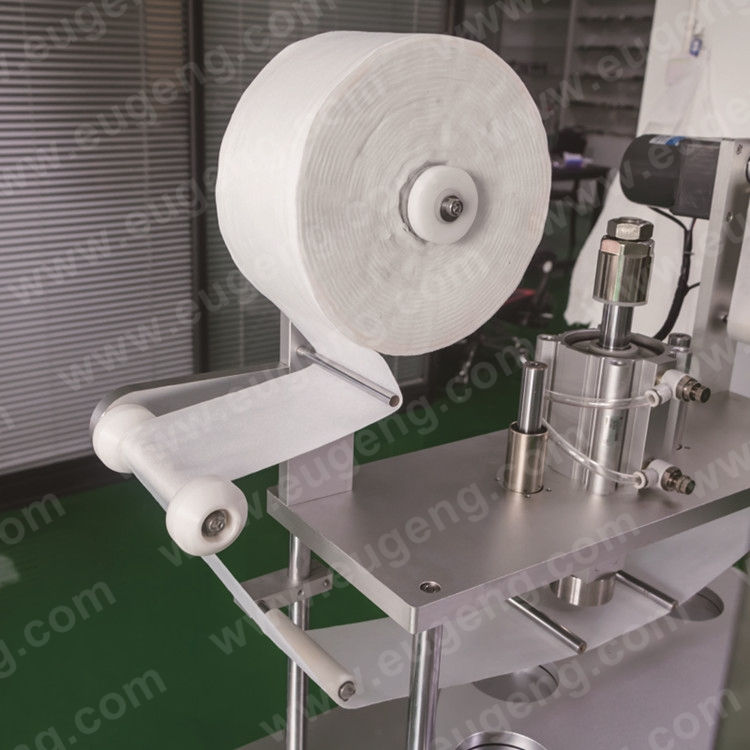

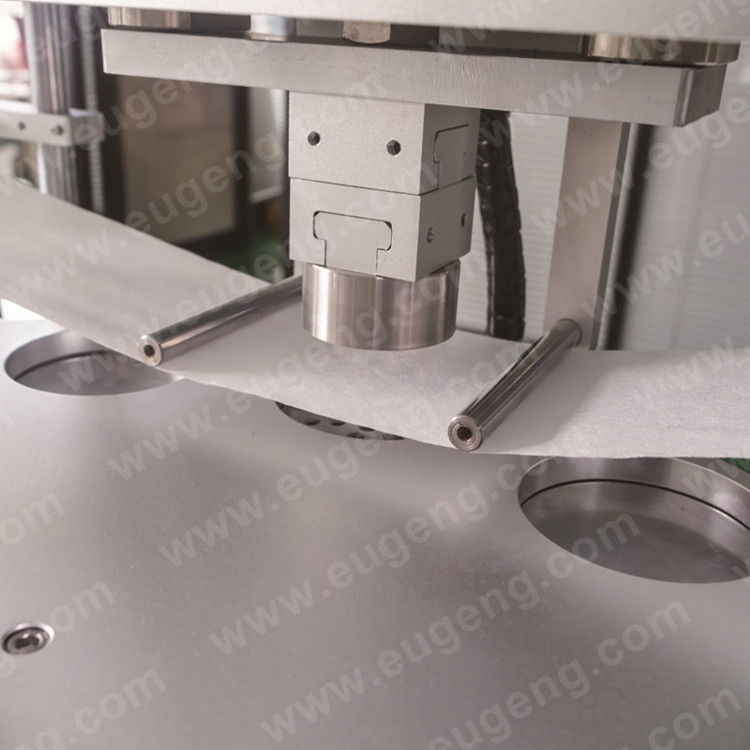

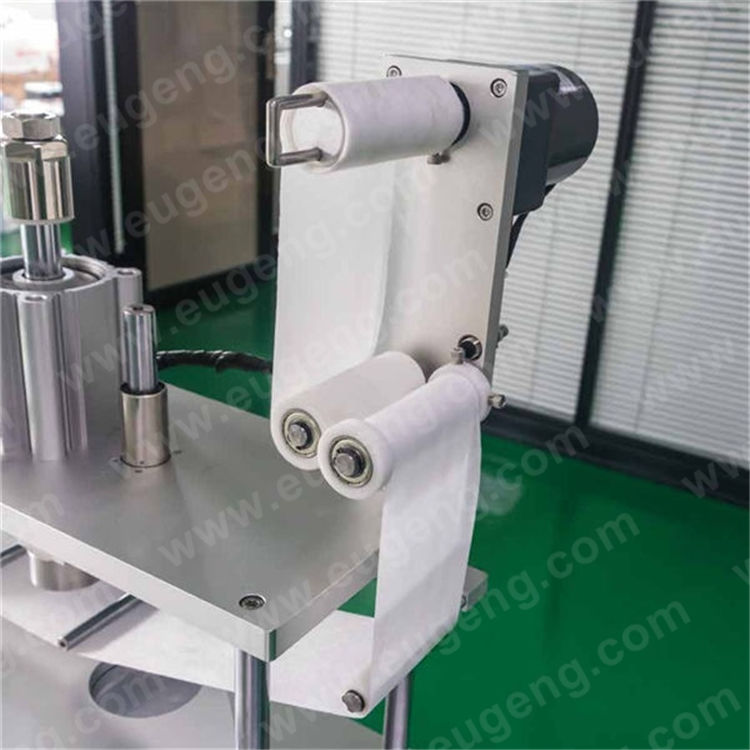

Machine Detail As Following Photo

Turntable

Discharge

Winding

Air cylinder pressing

Different godet need change different pressing head

Fabic size can be adjustabel

Touch screen operation panel

Emergency

Speed controller

Model EGBO-300 is bake oven design for the production of baked powder ,blush and eyeshadow

Capacity 1500pcs /cart

Feature

Aie dry baking with electric heating

Staines steel 304 inner frame

Max temp 300°C

Baking temp can be adjustable

Air blowing flowing can be adjustable

Machine Detail As Following Photo

Carts with wooden tray

Inner side og bake oven

Baking with crat

Model EGBS-01 is an semi-automatic scrap- ping machine design for the production of baked powder surface cleaning

Mold Scrapping knife& godet holder

Capacity 12-15pcs/min

Feature

Single holder for ceramic godet with vacuum fixed

Servo motor control knife moving up&down speed

Scrapping speed can be adjusted

Vacuum for collection powder make sure cleaning

Safety sensor protect operator hand cutting Touch screen operation

Standard Specifications

| Model No. | EGBS-01 |

| Production type | Manual |

| Output capacity/hr | 720-900 pcs |

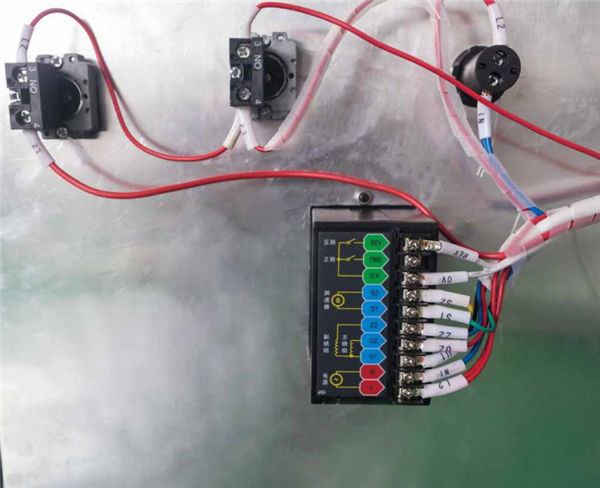

| Control Type | Servo motor |

| No. of knife | 1 |

| No. of holder | 1 |

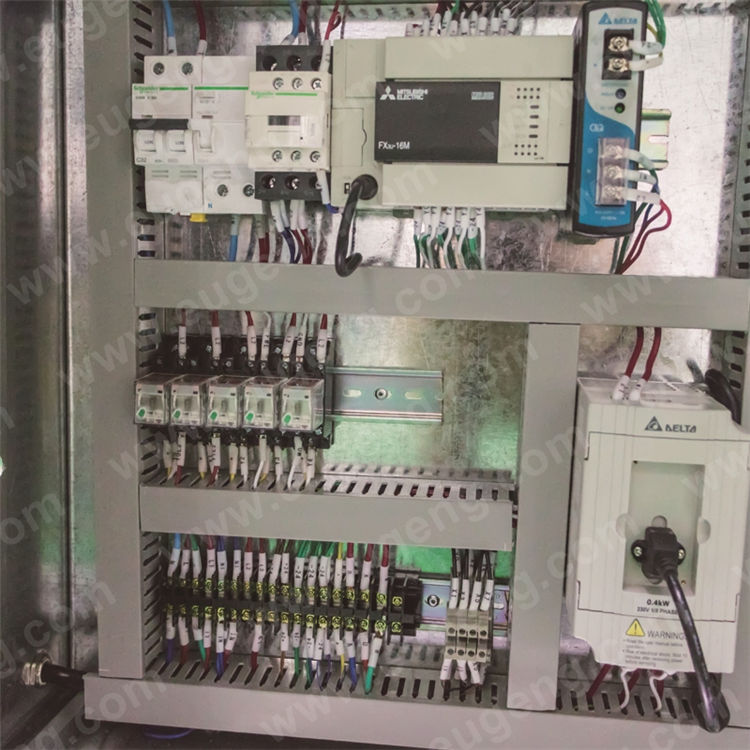

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 0.75kw |

| Dimension | 0.65×0.85×1.4m |

| Weight | 150kgs |

| Air input | 4-6 kgf |

Machine Detail As Following Photo

Turntable

Servo motor control up&down speed

Scrapping knife height can be adjusted

Safety sensor protect operator hand cutting

Emergency

Vacuum for collection the dust powder

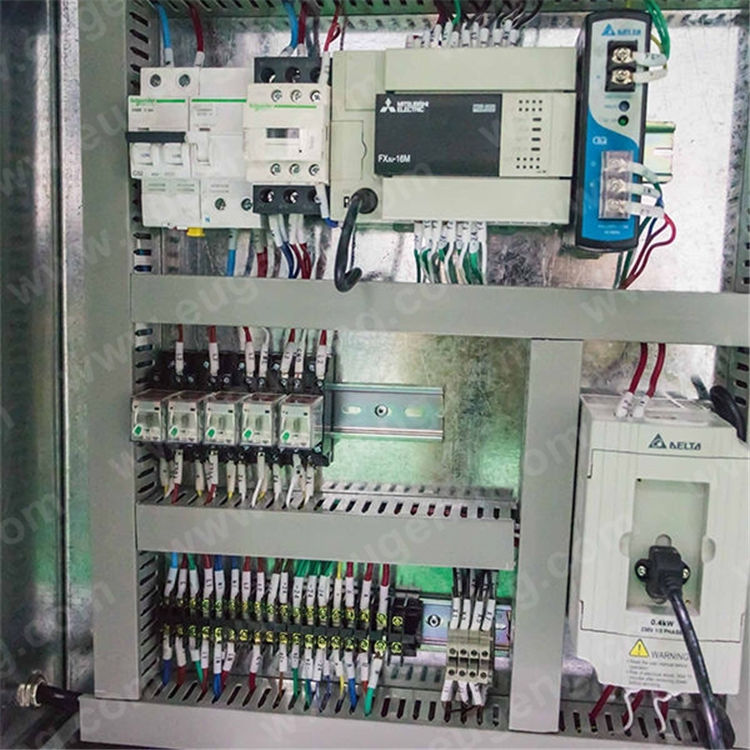

PLC MITSUBISHI

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Professional China Automatic Loose Powder Filling Machine - Baked Powder Production Line – Eugeng , The product will supply to all over the world, such as: Dominica, Ottawa, Philippines, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!