Semi Automatic Lipstick Filling Machine

Semi Automatic Lipstick Filling Machine Detail:

Model EGLF-1A semi automatic lipstick filling machine is a semi automatic hot filling machine. It is whole line including one hot lipstick filling machine,one lipstick cooling machine and one lipstick releasing machine.

This semi automatic lipstick filling machine is specially used for aluminum mold lipstick,silicone lipstick and lipstick pencil.

Semi automatic lipstick filling machine Capacity

4 molds/min, one mold with 12 holes,

so 48pcs lipstick/min,2880pcs lipstick in one hour

Semi automatic lipstick filling machine Mold

.Silicone mold

.Silicone mold holder

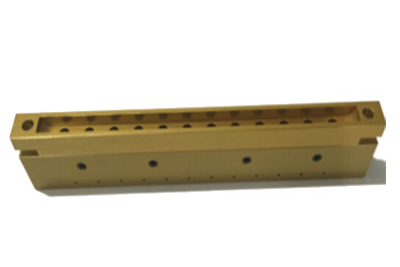

.Aluminum mold

Semi automatic lipstick filling machine Main parts:

Semi automatic hot lipstick filling machine:

.Mold pre-heating with touch heating plate and blowing hot air from top

· 1sets of 3 layers of jacketed vessels 25L capacity with heater and mixer

· Tank with automatic pre-heating system from Monday to Sunday ,pre-heating time can be adjustable

· Gear pump filling system with high Accuracy +/-0.3%

· Filling volume and filling speed controlled by digital input , and filling volume and speed can be adjustable

· Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick change over

· While filling while mold moving

Optional: Filling nozzle moving up and down for filling from bottom to up prevent bubble on lipstick.

Lipstick cooling machine:

. Automatic frost remove prevent water on the mold , and frost removing every 4 mins, and time can be adjustable

. Temp control by digital T.I.C, and Min is -20 Centigrade

. Automatic starting and stopping system control the real temperature within 2 Centigrade at setting temperature

. Stainless steel 304 frame, and spray foam in frame for preventing water dipping at the door

. Cooling compressor with both air and water cooling

Lipstick releasing machine

.Taking out the top mold by hand with tooling, and then put a guider mold for help put empty tubes with straight way

·Put the mold into semi-automatic releasing machine for insert lipstick into case

.Two button pressing designing for protect operator safe

·Releasing area have air blowing for aluminum mold and and vacuum for silicone mold optional as requirement

Product detail pictures:

Related Product Guide:

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for Semi Automatic Lipstick Filling Machine , The product will supply to all over the world, such as: French, Vietnam, Hungary, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.